Bolton Clinical Waste Incinerator: Difference between revisions

New page |

m →Plant |

||

| (4 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

{{#vardefine: epr|ZP3730XJ}}[[Category:High Temperature and Clinical Waste Incinerators]] | {{#vardefine: epr|ZP3730XJ}}[[Category:High Temperature and Clinical Waste Incinerators]] | ||

[[Clinical Waste Incinerator]] operated by [[Stericylce]] ([[SRCL]]) Ltd and based at the [[Royal Bolton Hospital]]. | |||

[[Clinical Waste Incinerator]] operated by | {{ClinIncin|EPR={{#var:epr}}|id=11}} | ||

[[File:Incinerator.JPG.gallery.jpg|350px|left|Bolton Clinical Incinerator at Royal Bolton Hospital - Source The Bolton News - All rights reserved]]__TOC__ | |||

<br clear='left'/> | |||

==Summary== | ==Summary== | ||

The [[Clinical Waste Incinerator]] is located at the Royal Bolton Hospital and is operated by Stericycle (SRCL) Ltd. The plant consists of a single stream, rated at 750 kg per hour or | The [[Clinical Waste Incinerator]] is located at the [[Royal Bolton Hospital]] and is operated by [[Stericycle]] ([[SRCL]]) Ltd. The plant consists of a single stream process, rated at 750 kg per hour or 6,570 tonnes per annum of solid wastes<ref name="SRCL">Annual Performance Report 2020, SRCL Ltd</ref>. The Primary Chamber operates a [[Rotary Kiln|rotary kiln]] design to provide good mixing of the waste coupled to sufficient retention time to burn the wastes to a high quality ash<ref name="SRCL" />. | ||

==Plant== | ==Plant== | ||

Waste is loaded mechanically into the Primary Chamber using a hydraulic lift and tip arrangement, to avoid any manual handling of the waste | Waste is loaded mechanically into the Primary Chamber using a hydraulic lift and tip arrangement, to avoid any manual handling of the waste<ref name="SRCL" />. The rotating action of the kiln provides good mixing of the waste, exposing fresh surfaces to [[combustion]] conditions. The [[combustion]] process is operated slightly in the [[wikipedia:Air–fuel ratio| sub-stoichiometric]] or starved air mode to produce [[wikipedia:Volatiles|volatile gases]] to fuel the Secondary Chamber while providing good burnout of the fixed carbon in the waste to produce [[IBA|bottom ash]]<ref name="SRCL" />. The [[IBA|bottom ash]] is discharged from the end of the [[Rotary Kiln|rotary kiln]] into an ash quench system to cool it rapidly, and from the ash quench pit it is discharged into storage skips. The skips of [[IBA|bottom ash]] are taken to a [[Environmental Permit|licensed]] [[Landfill]] Site for [[disposal]] as [[Non-Hazardous Waste]]<ref name="SRCL" />. | ||

The | The [[combustion]] gases produced in the Primary Chamber then pass into the Secondary Chamber, which operates at a minimum temperature of 850°C during start-up using [[Non-Hazardous Waste]]; and at a minimum temperature of 1000°C when [[Hazardous Waste]] may be loaded<ref name="SRCL" />. The Secondary Chamber provides a minimum of two seconds residence time under oxygen-rich conditions to combust any [[wikipedia:Carbon monoxide|Carbon Monoxide]] and [[wikipedia:Volatile organic compound|volatile organic compounds]] produced in the Primary Chamber<ref name="SRCL" />. | ||

The hot gases then pass through a [[wikipedia:Boiler (power generation)|boiler]] and dilution air system, which reduce the temperature from above 1000°C to around 160°C, before the [[Flue Gas|gases]] pass on to the [[wikipedia:Scrubber|flue gas treatment]] system<ref name="SRCL" />. | |||

{{EAIn|EPR={{#var:epr}}}} | |||

==References== | ==References== | ||

<references /> | <references /> | ||

Latest revision as of 07:31, 25 June 2021

Clinical Waste Incinerator operated by Stericylce (SRCL) Ltd and based at the Royal Bolton Hospital.

| Bolton Clinical Waste Incinerator | |

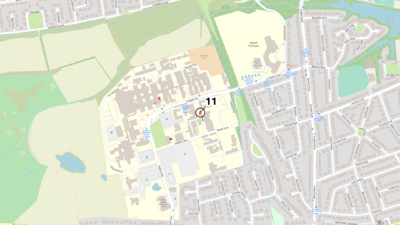

See HT & Clin → page for a larger UK Wide map. | |

| Waste Licence | ZP3730XJ |

| Operator | SRCL |

| Operational Capacity | 6,570tpa |

| Number of Lines | 1 |

| Region | North West |

Annual Report Data

| Year | Total In | Total Clinical | IBA Out | ACP Out | Op Hours

|

|---|---|---|---|---|---|

| 2019 | 6464 | 5758 | 1023 | 435 | 7525 |

| 2018 | |||||

| 2017 | |||||

| 2020 | 5110 | 5069 | 1020 | 305 | 7109 |

| 2021 | 5931 | 5931 | 880 | 242 | 7705 |

| 2022 | 5110 | 5051 | 843 | 238 | 7488 |

Summary

The Clinical Waste Incinerator is located at the Royal Bolton Hospital and is operated by Stericycle (SRCL) Ltd. The plant consists of a single stream process, rated at 750 kg per hour or 6,570 tonnes per annum of solid wastes[1]. The Primary Chamber operates a rotary kiln design to provide good mixing of the waste coupled to sufficient retention time to burn the wastes to a high quality ash[1].

Plant

Waste is loaded mechanically into the Primary Chamber using a hydraulic lift and tip arrangement, to avoid any manual handling of the waste[1]. The rotating action of the kiln provides good mixing of the waste, exposing fresh surfaces to combustion conditions. The combustion process is operated slightly in the sub-stoichiometric or starved air mode to produce volatile gases to fuel the Secondary Chamber while providing good burnout of the fixed carbon in the waste to produce bottom ash[1]. The bottom ash is discharged from the end of the rotary kiln into an ash quench system to cool it rapidly, and from the ash quench pit it is discharged into storage skips. The skips of bottom ash are taken to a licensed Landfill Site for disposal as Non-Hazardous Waste[1].

The combustion gases produced in the Primary Chamber then pass into the Secondary Chamber, which operates at a minimum temperature of 850°C during start-up using Non-Hazardous Waste; and at a minimum temperature of 1000°C when Hazardous Waste may be loaded[1]. The Secondary Chamber provides a minimum of two seconds residence time under oxygen-rich conditions to combust any Carbon Monoxide and volatile organic compounds produced in the Primary Chamber[1].

The hot gases then pass through a boiler and dilution air system, which reduce the temperature from above 1000°C to around 160°C, before the gases pass on to the flue gas treatment system[1].

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit ZP3730XJ, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated on Oct-24. The total reported tonnage arriving at the site was: 5,035.65t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|---|---|

| 02 01 03 | North West | 0.42 |

| 02 02 02 | North West | 0.11 |

| 02 02 02 | Scotland | 0.39 |

| 02 02 03 | Westmorland and Furness | 0.04 |

| 15 01 10* | North West | 0.1 |

| 18 01 01 | High Peak | 1.63 |

| 18 01 01 | North West | 0.27 |

| 18 01 03* | Ashfield | 0.19 |

| 18 01 03* | Bolsover | 0.07 |

| 18 01 03* | Burnley | 9.13 |

| 18 01 03* | Calderdale | 0.05 |

| 18 01 03* | Ceredigion | 0.1 |

| 18 01 03* | Cheltenham | 0.24 |

| 18 01 03* | Cherwell | 0.02 |

| 18 01 03* | Cheshire East | 63.4 |

| 18 01 03* | Cheshire West and Chester | 4.13 |

| 18 01 03* | Conwy | 0.29 |

| 18 01 03* | County Durham | 0.02 |

| 18 01 03* | Denbighshire | 4.54 |

| 18 01 03* | Derby | 1.91 |

| 18 01 03* | East Midlands | 5.85 |

| 18 01 03* | East Staffordshire | 0.13 |

| 18 01 03* | Gwynedd | 9.57 |

| 18 01 03* | Midlothian | 0.88 |

| 18 01 03* | Newark and Sherwood | 0.04 |

| 18 01 03* | North East | 0.05 |

| 18 01 03* | North Northamptonshire | 0.23 |

| 18 01 03* | North West | 2633.46 |

| 18 01 03* | North West Leicestershire | 0.4 |

| 18 01 03* | Northumberland | 0.08 |

| 18 01 03* | Pendle | 1.32 |

| 18 01 03* | Rhondda Cynon Taf | 0.19 |

| 18 01 03* | Rochdale | 0.97 |

| 18 01 03* | Scotland | 1.28 |

| 18 01 03* | South Ribble | 0.43 |

| 18 01 03* | South Staffordshire | 0.32 |

| 18 01 03* | St Helens | 53.08 |

| 18 01 03* | Trafford | 0.08 |

| 18 01 03* | Warwick | 0.25 |

| 18 01 03* | West Lothian | 0.27 |

| 18 01 03* | West Midlands | 7.22 |

| 18 01 03* | Westmorland and Furness | 5.64 |

| 18 01 03* | Wirral | 199.33 |

| 18 01 03* | Wrexham | 5.61 |

| 18 01 03* | Yorks & Humber | 1.68 |

| 18 01 04 | Burnley | 45.8 |

| 18 01 04 | Calderdale | 3.13 |

| 18 01 04 | Cheshire East | 16.31 |

| 18 01 04 | East Midlands | 0.13 |

| 18 01 04 | Gwynedd | 0.1 |

| 18 01 04 | High Peak | 17.64 |

| 18 01 04 | Midlothian | 0.14 |

| 18 01 04 | North West | 1364.5 |

| 18 01 04 | Pendle | 0.05 |

| 18 01 04 | Rochdale | 39.58 |

| 18 01 04 | Rossendale | 2.56 |

| 18 01 04 | Scotland | 0.32 |

| 18 01 04 | Tameside | 5.17 |

| 18 01 04 | Trafford | 10.83 |

| 18 01 04 | West Midlands | 0.04 |

| 18 01 04 | Wirral | 0.25 |

| 18 01 04 | Wrexham | 0.09 |

| 18 01 04 | Yorks & Humber | 0.11 |

| 18 01 06* | Ashfield | 0.05 |

| 18 01 06* | Cheshire East | 14.02 |

| 18 01 06* | Derby | 0.1 |

| 18 01 06* | Gwynedd | 76.69 |

| 18 01 06* | North West | 0.12 |

| 18 01 08* | Burnley | 0.11 |

| 18 01 08* | Cheltenham | 0.06 |

| 18 01 08* | Cheshire East | 46.16 |

| 18 01 08* | Cheshire West and Chester | 0.05 |

| 18 01 08* | Denbighshire | 0.92 |

| 18 01 08* | Derby | 0.03 |

| 18 01 08* | East Midlands | 0.19 |

| 18 01 08* | Gwynedd | 0.22 |

| 18 01 08* | Merton | 0.26 |

| 18 01 08* | North Northamptonshire | 0.06 |

| 18 01 08* | North West | 35.67 |

| 18 01 08* | North West Leicestershire | 0.52 |

| 18 01 08* | Scotland | 0.11 |

| 18 01 08* | St Helens | 2.36 |

| 18 01 08* | Warwick | 0.08 |

| 18 01 08* | West Midlands | 0.55 |

| 18 01 08* | Wirral | 8.22 |

| 18 01 09 | Burnley | 0.31 |

| 18 01 09 | Cheshire East | 0.06 |

| 18 01 09 | Cheshire West and Chester | 0.35 |

| 18 01 09 | Conwy | 0.03 |

| 18 01 09 | Denbighshire | 0.08 |

| 18 01 09 | Derby | 0.09 |

| 18 01 09 | East Midlands | 0.06 |

| 18 01 09 | Gwynedd | 0.14 |

| 18 01 09 | Newcastle upon Tyne | 0.06 |

| 18 01 09 | North East | 0.51 |

| 18 01 09 | North West | 86.49 |

| 18 01 09 | Scotland | 0.69 |

| 18 01 09 | South Staffordshire | 0.02 |

| 18 01 09 | Stratford-on-Avon | 0.01 |

| 18 01 09 | Tameside | 0.06 |

| 18 01 09 | West Lothian | 0.59 |

| 18 01 09 | West Midlands | 0.7 |

| 18 01 09 | Wirral | 6.92 |

| 18 01 09 | Wrexham | 0.11 |

| 18 02 02* | Cheshire East | 10.41 |

| 18 02 02* | Cheshire West and Chester | 54.81 |

| 18 02 02* | City of Edinburgh | 0.48 |

| 18 02 02* | Midlothian | 0.48 |

| 18 02 02* | North West | 25.36 |

| 18 02 02* | Scotland | 1.22 |

| 18 02 02* | South Ribble | 56.31 |

| 18 02 02* | West Midlands | 0.37 |

| 18 02 02* | Wirral | 0.01 |

| 18 02 03 | Cheshire East | 0.57 |

| 18 02 03 | North West | 10.26 |

| 18 02 03 | West Midlands | 0.07 |

| 18 02 03 | Westmorland and Furness | 1.2 |

| 18 02 05* | Cheshire West and Chester | 0.07 |

| 18 02 05* | South Ribble | 0.33 |

| 18 02 07* | Merton | 0.45 |

| 18 02 07* | North West | 0.1 |

| 18 02 07* | South Ribble | 0.33 |

| 18 02 08 | Merton | 0.81 |

| 18 02 08 | North East | 0.16 |

| 18 02 08 | North West | 0.9 |

| 18 02 08 | South Ribble | 24.14 |

| 20 01 99 | Cheshire East | 2.09 |

| 20 01 99 | North West | 38.73 |