Thermal Desorption: Difference between revisions

No edit summary |

→Types of Thermal Desorption Systems: web links |

||

| Line 12: | Line 12: | ||

There are two principle types of approach to introducing heat to the process - either through direct application of heat or indirect application of heat. Sources of indirect heat include natural gas or oil fired burners, thermal oil, electrical (eg infra-red or microwave) and friction<ref name='EA'/>. | There are two principle types of approach to introducing heat to the process - either through direct application of heat or indirect application of heat. Sources of indirect heat include natural gas or oil fired burners, thermal oil, electrical (eg infra-red or microwave) and friction<ref name='EA'/>. | ||

Operation mode can be either a batch (ie as a sealed oven) or continuous (ie rotary kiln design)<ref name='EA'/>. | Operation mode can be either a batch (ie as a sealed oven) or continuous (ie [[Rotary Kiln|rotary kiln]] design)<ref name='EA'/>. | ||

==References== | ==References== | ||

<references /> | <references /> | ||

Latest revision as of 12:59, 28 June 2021

Thermal Desorption is described in the EA guidance 382_12 as a treatment process whereby heat is applied to materials, such as waste soils, sediments, slurries and filter cakes, in order to remove (vaporise) volatile contaminants (e.g. oils and solvents)[1].

Overview

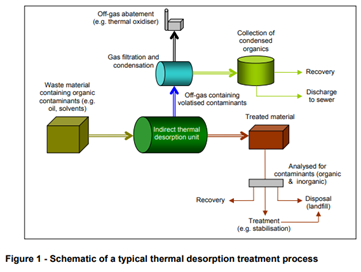

Thermal Desorption is described in the EA guidance 382_12 as a treatment process whereby heat is applied to materials, such as waste soils, sediments, slurries and filter cakes, in order to remove (vaporise) volatile contaminants (e.g. oils and solvents). Along with such volatile contaminants, thermal desorption will also vaporise water contained within the material and therefore a thermal desorption plant also functions, and may be referred to, as a “dryer”. A schematic of a typical indirect thermal desorption process is summarised in Figure 1 below[1].

This guidance provides greater detail to the overarching Sector Guidance Note IPPC S5.06[2]

Types of Thermal Desorption Systems

There are two principle types of approach to introducing heat to the process - either through direct application of heat or indirect application of heat. Sources of indirect heat include natural gas or oil fired burners, thermal oil, electrical (eg infra-red or microwave) and friction[1].

Operation mode can be either a batch (ie as a sealed oven) or continuous (ie rotary kiln design)[1].