Blackburn Meadows Renewable Energy Plant: Difference between revisions

Created page with "Category:Biomass EfW Plants {{BiomassPlant|NAME=Blackburn Meadows|id=15}} 400px|left|Blackburn Meadows. BDP, 2018. ==Sum..." |

No edit summary |

||

| (9 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Biomass EfW Plants]] | A Biomass Waste [[Combined Heat and Power | combined heat and power]] (CHP) EFW facility [[Blackburn Meadows Renewable Energy Plant]] uses a feedstock of [[Wood Waste]] to generate 29 MWe and up to 25 MWth. The facility is located on the site of the former Tinsley cooling towers in Sheffield, and the [[Wood Waste]] is sourced locally within a 50-mile of the plant. | ||

{{BiomassPlant|NAME=Blackburn Meadows|id=15}} | [[Category:Biomass EfW Plants]]{{#vardefine: epr|LP3131TA}} | ||

[[File:Blackburn-meadows--sheffield 06.jpg|400px|left|Blackburn Meadows. BDP, 2018.]] | {{BiomassPlant|NAME=Blackburn Meadows Renewable Energy Plant|id=15|EPR={{#var: epr}}}} | ||

[[File:Blackburn-meadows--sheffield 06.jpg|400px|left|Blackburn Meadows. BDP, 2018.]]__TOC__ | |||

<br clear='left'/> | |||

<ref>[https://www.eonenergy.com/business/why-eon/case-studies/blackburn-meadows.html/ Blackburn Meadows CHP Site Photo]All Rights Reserved</ref> | |||

==Summary== | ==Summary== | ||

A Biomass Waste [[Combined Heat and Power | combined heat and power]] (CHP) EFW facility [[Blackburn Meadows Renewable Energy Plant]] uses a feedstock of [[Wood Waste]] to generate 29 MWe and up to 25 MWth. The facility is located on the site of the former Tinsley cooling towers in Sheffield, and the [[Wood Waste]] is sourced locally within a 50-mile of the plant. The generated electricity is exported to the national grid and the heat is supplied as hot water to local businesses through a district heating network, including the Sheffield Arena and Forgemaster Steel Works<ref name="ref1" >E.ON, 2020. [https://www.eonenergy.com/business/why-eon/case-studies/blackburn-meadows.html Blackburn Meadows | Business Case Studies | E.ON. Online. Eonenergy.com. [Accessed 6 April 2020]].</ref>. | |||

The Blackburn Meadows facility is operated by [[E.ON Energy]] and became operational in 2015 after beginning construction in 2011<ref name="ref2" >BDP., 2018. [http://www.bdp.com/en/projects/a-e/blackburn-meadows-biomass-plant/ Blackburn Meadows Biomass Plant - BDP.Com. Online. Bdp.com. [Accessed 6 April 2020]].</ref>. | |||

The Blackburn Meadows facility is operated by E.ON Energy and became operational in 2015 after beginning construction in 2011<ref name="ref2" >BDP., 2018. [http://www.bdp.com/en/projects/a-e/blackburn-meadows-biomass-plant/ Blackburn Meadows Biomass Plant - BDP.Com. Online. Bdp.com. [Accessed 6 April 2020].</ref>. | |||

==Plant== | ==Plant== | ||

The facility had a 10 MW battery installed after it was awarded a contract to support the national grid’s stability requirements, which became operational in 2017<ref name="ref1"/>. | |||

The facility | |||

The unique architectural work was undertaken by BDP, which includes an orange translucent clad boiler house that is internally illuminated<ref name="ref2"/>. | The unique architectural work was undertaken by BDP, which includes an orange translucent clad boiler house that is internally illuminated<ref name="ref2"/>. | ||

The facility cost £120 million to develop<ref>Bioenergy Insight, 2014. [https://www.bioenergy-news.com/news/e-ons-blackburn-meadows-biomass-plant-generates-electricity/ E.ON's Blackburn Meadows Biomass Plant Generates Electricity. Online. Bioenergy Insight. [Accessed 6 April 2020].</ref>. | The facility cost £120 million to develop<ref>Bioenergy Insight, 2014. [https://www.bioenergy-news.com/news/e-ons-blackburn-meadows-biomass-plant-generates-electricity/ E.ON's Blackburn Meadows Biomass Plant Generates Electricity. Online. Bioenergy Insight. [Accessed 6 April 2020]].</ref>. It has an [[Andritz]] boiler. | ||

{{BioSustain|EPR={{#var: epr}}}} | |||

{{EAIn|EPR={{#var: epr}}}} | |||

==References== | ==References== | ||

<references/> | <references/> | ||

Latest revision as of 06:50, 15 August 2022

A Biomass Waste combined heat and power (CHP) EFW facility Blackburn Meadows Renewable Energy Plant uses a feedstock of Wood Waste to generate 29 MWe and up to 25 MWth. The facility is located on the site of the former Tinsley cooling towers in Sheffield, and the Wood Waste is sourced locally within a 50-mile of the plant.

| Blackburn Meadows Renewable Energy Plant Operational | |

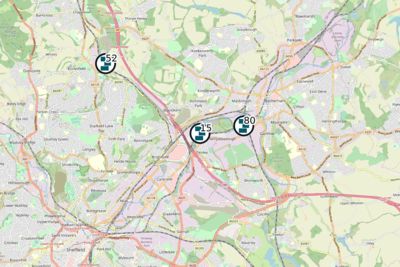

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | E-On UK Blackburn Meados Ltd |

| Capacity | 30 MWe |

| Feedstock | Waste Wood |

| EPR (Waste Licence) | LP3131TA |

| ROC | Yes |

| CfD | |

| CHP | Yes |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|---|---|---|---|---|

| 2017 | 202183 | 0 | 0 | 0 | 202183 |

| 2018 | 214135 | 0 | 0 | 0 | 214135 |

| 2019 | 200098 | 0 | 0 | 0 | 200098 |

| 2020 | 149665 | 0 | 0 | 0 | 149665 |

| 2021 | 207643 | 0 | 0 | 0 | 207643 |

| 2022 | 199548 | 0 | 0 | 0 | 199548 |

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|---|---|---|---|

| 2017 | 4500 | 2.23% | 5265 | 2.60% |

| 2018 | 3636 | 1.70% | 5324 | 2.49% |

| 2019 | 4463 | 2.23% | 5116 | 2.56% |

| 2020 | 3580 | 2.39% | 3968 | 2.65% |

| 2021 | 4084 | 1.97% | 5267 | 2.54% |

| 2022 | 4669 | 2.34% | 5207 | 2.61% |

Summary

A Biomass Waste combined heat and power (CHP) EFW facility Blackburn Meadows Renewable Energy Plant uses a feedstock of Wood Waste to generate 29 MWe and up to 25 MWth. The facility is located on the site of the former Tinsley cooling towers in Sheffield, and the Wood Waste is sourced locally within a 50-mile of the plant. The generated electricity is exported to the national grid and the heat is supplied as hot water to local businesses through a district heating network, including the Sheffield Arena and Forgemaster Steel Works[2].

The Blackburn Meadows facility is operated by E.ON Energy and became operational in 2015 after beginning construction in 2011[3].

Plant

The facility had a 10 MW battery installed after it was awarded a contract to support the national grid’s stability requirements, which became operational in 2017[2].

The unique architectural work was undertaken by BDP, which includes an orange translucent clad boiler house that is internally illuminated[3].

The facility cost £120 million to develop[4]. It has an Andritz boiler.

Annual Sustainability Tonnage Input/Fuel

The tonnage[5] received by the plant in the most recent Annual Sustainability Report and for the previous 3 years for 2020/21 was reported by Ofgem as below[6]:

| Year | Waste Wood (m3) | Waste Wood (t) | Straw | Miscanthus | Arboricultrual Waste | Sawmill Residue | Foresrty Residue | Round Wood | Short Rotation Coppice | MBM | Other Material |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2020/21 | 0 | 142827 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2019/20 | 0 | 203490 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2018/19 | 0 | 208327 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2017/18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit LP3131TA, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated on Oct-24. The total reported tonnage arriving at the site was: 208,957.68t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|---|---|

| 19 12 07 | Berkshire | 67.3 |

| 19 12 07 | Buckinghamshire | 5944.52 |

| 19 12 07 | Cannock Chase | 5254.66 |

| 19 12 07 | City of London | 5015.06 |

| 19 12 07 | Cumbria | 766.18 |

| 19 12 07 | Doncaster | 2251.4 |

| 19 12 07 | East Riding of Yorkshire | 49769.86 |

| 19 12 07 | Greater London | 11896.92 |

| 19 12 07 | Guildford | 942 |

| 19 12 07 | Hampshire | 3930.68 |

| 19 12 07 | Hertfordshire | 26.3 |

| 19 12 07 | Lancashire | 845.62 |

| 19 12 07 | Leicestershire | 505.64 |

| 19 12 07 | Lincoln | 1625.16 |

| 19 12 07 | Lincolnshire | 6970.02 |

| 19 12 07 | London | 1939.92 |

| 19 12 07 | North East | 429.82 |

| 19 12 07 | North Yorkshire | 567.04 |

| 19 12 07 | Northamptonshire | 690.7 |

| 19 12 07 | Nottingham | 3971.78 |

| 19 12 07 | Nottinghamshire | 9288.4 |

| 19 12 07 | Staffordshire | 8020.88 |

| 19 12 07 | Surrey | 1730.4 |

| 19 12 07 | West Lancashire | 21.38 |

| 19 12 07 | West Midlands | 81589.96 |

| 19 12 07 | Winchester | 776.7 |

| 19 12 07 | Yorks & Humber | 4119.38 |

References

- ↑ Blackburn Meadows CHP Site PhotoAll Rights Reserved

- ↑ 2.0 2.1 E.ON, 2020. Blackburn Meadows | Business Case Studies | E.ON. Online. Eonenergy.com. [Accessed 6 April 2020].

- ↑ 3.0 3.1 BDP., 2018. Blackburn Meadows Biomass Plant - BDP.Com. Online. Bdp.com. [Accessed 6 April 2020].

- ↑ Bioenergy Insight, 2014. E.ON's Blackburn Meadows Biomass Plant Generates Electricity. Online. Bioenergy Insight. [Accessed 6 April 2020].

- ↑ In the case of EfW plants with gasification technology the figures are reported in terms of cubic metres of syngas produced rather than tonnes used

- ↑ Biomass Sustainability Dataset 2020-21