Markley Group Biomass: Difference between revisions

Additon of a different picture. |

No edit summary |

||

| (9 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Biomass EfW Plants]] | A [[Biomass EfW]] facility, [[Markley Group Biomass]] is located at [[Markley Group]] premises in Hardwicke, Gloucestershire, which generates 2.1MW from c. 2,300 tonnes of [[Wood Waste]] from its commercial business<ref name="BIO">[https://www.bioenergy-news.com/news/markey-group-opens-1-1m-biomass-facility/ Bioenergy News]</ref>. | ||

{{BiomassPlant|NAME=Markley Group Biomass|id= | [[Category:Biomass EfW Plants]]{{#vardefine: epr|tbc4}} | ||

[[File:Premiere Kitchens Biomass Facility.jpg|300px|left|Premiere Kitchens Biomass Facility]] | {{BiomassPlant|NAME=Markley Group Biomass|id=57|EPR={{#var: epr}}}} | ||

[[File:Premiere Kitchens Biomass Facility.jpg|300px|left|Premiere Kitchens Biomass Facility]]__TOC__ | |||

<br clear="left"/> | <br clear="left"/> | ||

==Summary== | ==Summary== | ||

A | A [[Biomass EfW]] facility, [[Markley Group Biomass]] is located at [[Markley Group]] premises in Hardwicke, Gloucestershire, which generates 2.1MW from c. 2,300 tonnes of [[Wood Waste]] from its commercial business<ref name="BIO" />. | ||

In 2012, Gloucester based | In 2012, Gloucester based Markley Group opened a £1.1m biomass facility which runs on waste wood generated by the subsidiary of Markley Group, [[Premiere Kitchens]]<ref name="BIO" />. Each year Premiere Kitchens creates approximately 2,350 tonnes of waste wood in the form of extracted chipboard dust and residual off-cuts, which is used in the plant to generate all of the heating and hot water required for the company's site at Hardwicke<ref name="BIO" />. | ||

Following the installation of the biomass facility, | Following the installation of the biomass facility, Markley Group were able to remove its mains gas supply and as a result the company reduces its carbon emissions by more than c.1,200 tonnes per year<ref name="BIO" />. | ||

==Plant== | ==Plant== | ||

The plant was commissioned by UK-based Indusvent Limited | The plant was commissioned by UK-based [[Indusvent Limited]] who were instructed to design, supply and install a complete turnkey project which included a dust extraction and filtration system for production machinery, a sealed chipboard dust and chips transportation system, a 300m<sup>3</sup> storage silo with hydraulic moving floor discharge, shredding of off-cuts and burning of the collected material to provide hot water and heating for both the office and factory heating<ref>[http://www.indusvent.com/project-installations/biomass/energy-efficient-2-1-mw-biomass-plant-for-premiere-kitchens.aspx Indusvent Website]</ref>. The system features a 2.1 MW hot water boiler manufactured by Danish based [[Justsen Energiteknik A/S]]<ref name="BIO" />. The burning of the [[Wood Waste]] in the boiler is controlled automatically to maximise efficiency with results monitored both on site and at the manufacturers premises in Denmark<ref name="BIO" />. | ||

== | {{BioSustain|EPR={{#var: epr}}}} | ||

{{EAIn|EPR={{#var: epr}}}} | |||

The tonnage received by the plant is a mixture of [[Wood Waste]] off-cuts from its kitchen construction business and is essentially 'internal' material that is not reported in the [[Annual Sustainability Report]] data. | |||

==References== | ==References== | ||

Latest revision as of 08:05, 15 August 2022

A Biomass EfW facility, Markley Group Biomass is located at Markley Group premises in Hardwicke, Gloucestershire, which generates 2.1MW from c. 2,300 tonnes of Wood Waste from its commercial business[1].

| Error: no local variable "site" has been set. Error: no local variable "status" has been set. | |

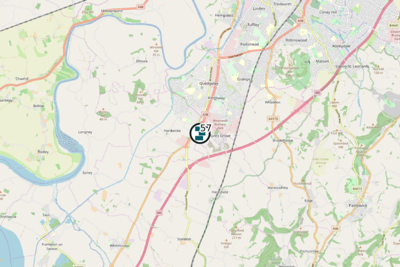

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Error: no local variable "operator" has been set. |

| Capacity | Error: no local variable "capacity" has been set. MWe |

| Feedstock | Error: no local variable "mainfeed" has been set. |

| EPR (Waste Licence) | Error: no local variable "epr" has been set. |

| ROC | Error: no local variable "roc" has been set. |

| CfD | Error: no local variable "cfdcap" has been set. |

| CHP | Error: no local variable "chp" has been set. |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

A Biomass EfW facility, Markley Group Biomass is located at Markley Group premises in Hardwicke, Gloucestershire, which generates 2.1MW from c. 2,300 tonnes of Wood Waste from its commercial business[1].

In 2012, Gloucester based Markley Group opened a £1.1m biomass facility which runs on waste wood generated by the subsidiary of Markley Group, Premiere Kitchens[1]. Each year Premiere Kitchens creates approximately 2,350 tonnes of waste wood in the form of extracted chipboard dust and residual off-cuts, which is used in the plant to generate all of the heating and hot water required for the company's site at Hardwicke[1].

Following the installation of the biomass facility, Markley Group were able to remove its mains gas supply and as a result the company reduces its carbon emissions by more than c.1,200 tonnes per year[1].

Plant

The plant was commissioned by UK-based Indusvent Limited who were instructed to design, supply and install a complete turnkey project which included a dust extraction and filtration system for production machinery, a sealed chipboard dust and chips transportation system, a 300m3 storage silo with hydraulic moving floor discharge, shredding of off-cuts and burning of the collected material to provide hot water and heating for both the office and factory heating[2]. The system features a 2.1 MW hot water boiler manufactured by Danish based Justsen Energiteknik A/S[1]. The burning of the Wood Waste in the boiler is controlled automatically to maximise efficiency with results monitored both on site and at the manufacturers premises in Denmark[1].

Annual Sustainability Tonnage Input/Fuel

The tonnage[3] received by the plant in the most recent Annual Sustainability Report and for the previous 3 years for Error: no local variable "asyear" has been set. was reported by Ofgem as below[4]:

| Year | Waste Wood (m3) | Waste Wood (t) | Straw | Miscanthus | Arboricultrual Waste | Sawmill Residue | Foresrty Residue | Round Wood | Short Rotation Coppice | MBM | Other Material |

|---|

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit tbc4, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data used is from the most recent returns. The total reported tonnage arriving at the site was: Expression error: Unexpected < operator.t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|

The tonnage received by the plant is a mixture of Wood Waste off-cuts from its kitchen construction business and is essentially 'internal' material that is not reported in the Annual Sustainability Report data.

References

- ↑ 1.0 1.1 1.2 1.3 1.4 1.5 1.6 Bioenergy News

- ↑ Indusvent Website

- ↑ In the case of EfW plants with gasification technology the figures are reported in terms of cubic metres of syngas produced rather than tonnes used

- ↑ Biomass Sustainability Dataset 2020-21