Padeswood Cement Kiln: Difference between revisions

Arctellion (talk | contribs) No edit summary |

No edit summary |

||

| (11 intermediate revisions by 4 users not shown) | |||

| Line 1: | Line 1: | ||

[[Padeswood Cement Kiln]] is located in Mold and is owned by [[Hanson Cement]]. | |||

{{CementKiln|EPR=BL1096IB|id=7}} | {{CementKiln|EPR=BL1096IB|id=7}} | ||

[[Category:Cement Kilns]] | [[Category:Cement Kilns]] | ||

[[File:New Kiln at the Cement works, Padeswood - geograph.org.uk - 49768.jpg|400px|left|New Kiln at the Cement works, Padeswood - geograph.org.uk - 49768.jpg]]__TOC__ | |||

<br clear='left'/> | |||

== | ==Overview== | ||

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland<ref>https://www.cementkilns.co.uk/index.html</ref> extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Padeswood started manufacturing clinker in 1949 and up to 2015 had produced 31 million tonnes of clinker through 4 rotary kilns over this period. | |||

==Ownership== | |||

* 1949 to 1968 Tunnel Portland Cement Co. Ltd | |||

* 1968 to 1986 Tunnel Cement Ltd | |||

* 1986 to 2009 Castle Cement Ltd (Rio Tino Zinc (RTZ) to 1989, Scancem to 1999, HeidlebergCement to 2009) | |||

* 2009 to Present [[Hanson Cement UK]] (owned by [[HeidelbergCement]]) | |||

==The Process at Padeswood== | |||

The process at the site is an air-separated precalciner kiln, supplied by FLS (FLSmidth) which allows for the burning of alternative fuels<ref>[https://www.hanson-communities.co.uk/en/sites/padeswood-cement-works-community-page Hanson/Padeswood Community Website/]</ref>. | |||

==Raw Materials== | |||

The primary raw materials are Carboniferous Limestone from Cefn Mawr Quarry, with coal measure shale and colliery waste from the Llay Main colliery tip, moving to Bersham Colliery in the future. | |||

{{NHLFTable|Permit=BL1096IB}} | |||

{{EAIn|EPR=BL1096IB|CK=T}} | |||

The majority of the tonnage listed was used for the primary purpose of substituting fuel requirements in the plant. In 2015 the tonnage was almost exclusively for the use of fuel and included [[Cemfuel]] (liquid waste solvents) 13,422 tonnes, [[MBM]] 7,284 tonnes and [[SRF]] 19,007<ref>[https://www.hanson-communities.co.uk/en/search?keywords=padeswood Link to pdf on Hanson Website - 2015 Annual Performance Report for Padeswood]</ref>. | |||

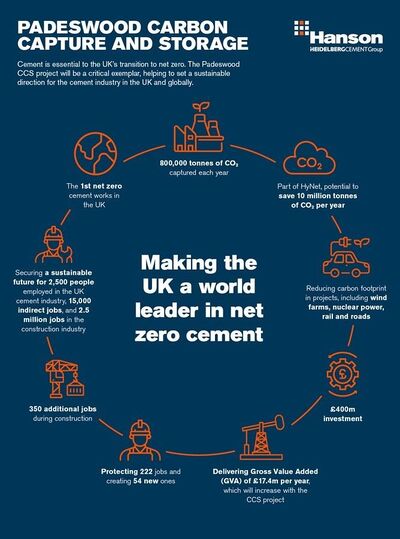

==Carbon Capture and Storage== | |||

In August 2022 it was announced that Padeswood would be part of the Hynet cluster for [[CCUS]]. | |||

[[File:1660039828001.jpg|400px|left|Infographic from linkedIn - all rights reserved Hanson]]<br clear='left'/> | |||

==References== | ==References== | ||

<references /> | <references /> | ||

Latest revision as of 09:51, 10 November 2022

Padeswood Cement Kiln is located in Mold and is owned by Hanson Cement.

| Padeswood Cement Kiln | |

See Cement Kilns → page for a larger UK Wide map. | |

| Waste Licence | BL1096IB |

| Operator | Hanson Cement |

| Parent Company | Heidelberg Cement Group |

| Clinker Capacity | 0.82 Mt |

Summary site information collated from a variety of sources.

Overview

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland[1] extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Padeswood started manufacturing clinker in 1949 and up to 2015 had produced 31 million tonnes of clinker through 4 rotary kilns over this period.

Ownership

- 1949 to 1968 Tunnel Portland Cement Co. Ltd

- 1968 to 1986 Tunnel Cement Ltd

- 1986 to 2009 Castle Cement Ltd (Rio Tino Zinc (RTZ) to 1989, Scancem to 1999, HeidlebergCement to 2009)

- 2009 to Present Hanson Cement UK (owned by HeidelbergCement)

The Process at Padeswood

The process at the site is an air-separated precalciner kiln, supplied by FLS (FLSmidth) which allows for the burning of alternative fuels[2].

Raw Materials

The primary raw materials are Carboniferous Limestone from Cefn Mawr Quarry, with coal measure shale and colliery waste from the Llay Main colliery tip, moving to Bersham Colliery in the future.

Waste Tonnage, EWC List

The table shows a list of the Waste for the Permit BL1096IB, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated in Oct-23. The total reported tonnage arriving at the site was: 63,764.32t.

| EWC Code | Description | Tonnes In |

|---|---|---|

| 02 02 03 | materials unsuitable for consumption or processing | 2030.06 |

| 10 02 13* | sludges and filter cakes from gas treatment containing dangerous substances | 9536.76 |

| 10 11 03 | waste glass-based fibrous materials | 6.2 |

| 19 02 08* | liquid combustible wastes containing dangerous substances | 13958.39 |

| 19 12 10 | combustible waste (refuse derived fuel) | 38232.91 |

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit BL1096IB, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated on Oct-23. The total reported tonnage arriving at the site was: 63,764.32t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|---|---|

| 02 02 03 | West Yorkshire | 2030.06 |

| 10 02 13* | Sheffield | 9536.76 |

| 10 11 03 | Flintshire | 6.2 |

| 19 02 08* | Lancashire | 13958.39 |

| 19 12 10 | Lancashire | 29166.44 |

| 19 12 10 | Middlesbrough | 4839.8 |

| 19 12 10 | Stockton-on-Tees | 4226.67 |

The majority of the tonnage listed was used for the primary purpose of substituting fuel requirements in the plant. In 2015 the tonnage was almost exclusively for the use of fuel and included Cemfuel (liquid waste solvents) 13,422 tonnes, MBM 7,284 tonnes and SRF 19,007[3].

Carbon Capture and Storage

In August 2022 it was announced that Padeswood would be part of the Hynet cluster for CCUS.