Cauldon Cement Kiln: Difference between revisions

Arctellion (talk | contribs) m Arctellion moved page Cauldon to Cauldon Cement Kiln: renamed to reduce confusion with other pages. |

No edit summary |

||

| (12 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[Cauldon Cement Kiln]] is located in Stoke-on-Trent and is owned by [[Aggregate Industries]]. | |||

{{CementKiln|EPR=TP3334AW|id=2}} | {{CementKiln|EPR=TP3334AW|id=2}} | ||

[[Category:Cement Kilns]] | [[Category:Cement Kilns]] | ||

[[File:Cauldon2006 pic.jpg|400px|left|Cauldron Cement Works - source Alan Murray-Rust 2006]]__TOC__ | |||

<br clear='left'/> | |||

== | ==Overview== | ||

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland<ref>https://www.cementkilns.co.uk/index.html</ref> extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Cauldon started operating in 1957 and up to 2015 had produced 40 million tonnes of clinker through 4 rotary kilns over this period. | |||

==Ownership== | |||

* 1957 to 2001 BPCM (G&T Earles) (Blue Circle) | |||

* 2001 to 2013 Lafarge | |||

* 2013 to 2015 Lafarge Tarmac | |||

* 2015 to Present [[LafargeHolcim]] (Lafarge Cement is part of [[Aggregate Industries]], which itself is owned by [[LafargeHolcim]]<ref>[https://www.aggregate.com/our-businesses/lafarge-cement/bulk-cement/our-history Aggregate Industries Website Summarizing history of ownership]</ref>) | |||

==The Process at Cauldon== | |||

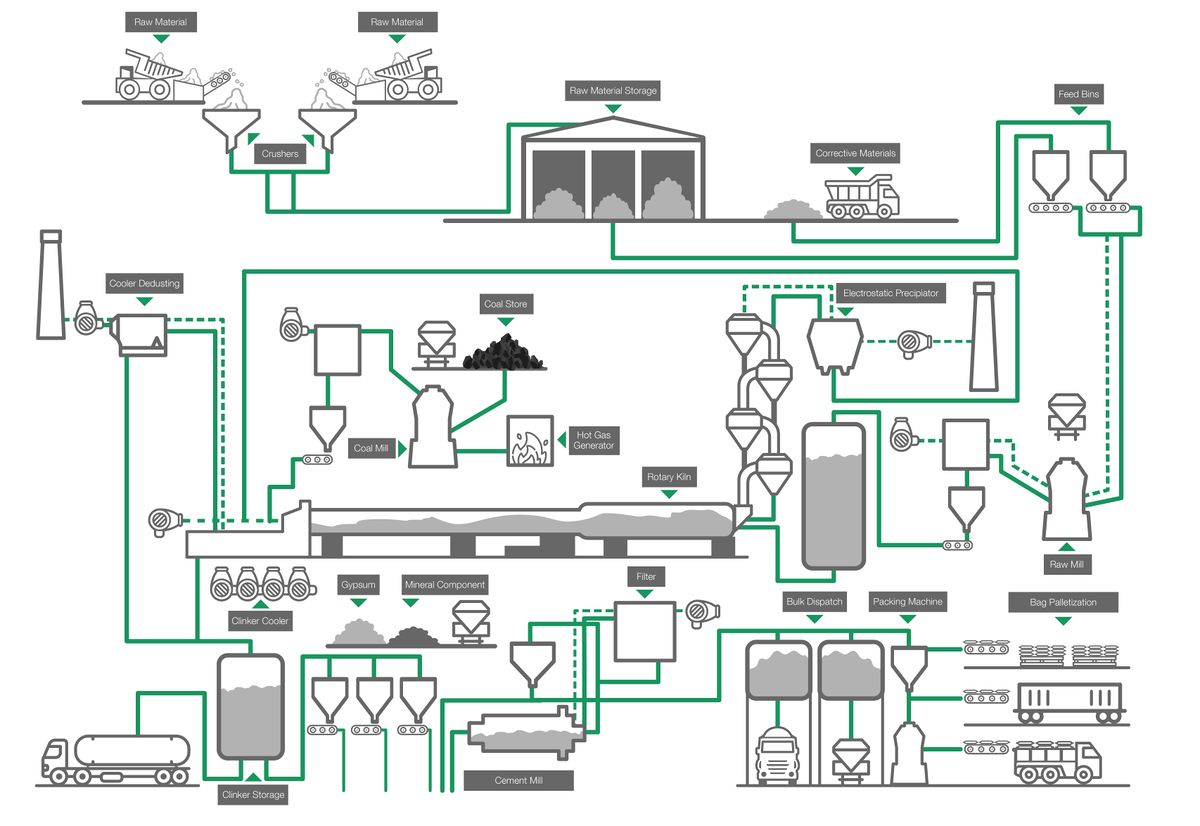

The following summary diagram is from the [[Aggregate Industries]] website<ref>[https://www.aggregate.com/our-businesses/lafarge-cement/bulk-cement/making-cement How we make cement at Cauldon]</ref> which is a 'dry process': | |||

[[File:Lafarge-making-cement-dry-process cauldron.jpg|1200px|left|Schematic of Cauldron dry manufacturing process - source Aggregate Industries website]]__TOC__ | |||

<br clear='left'/> | |||

==Raw Materials== | |||

The primary raw materials are Carboniferous Limestone from Cauldon Low Quarry to the south of the site and Carboniferous Shale in a nearby deposit to the north and west of the plant. | |||

{{NHLFTable|Permit=TP3334AW}} | |||

{{EAIn|EPR=TP3334AW|CK=T}} | |||

In early June 2021 [[Aggregate Industries]] confirmed that they had broken ground on a £13m project to increase their ability to handle up to 100,000 tonnes per annum of [[RDF|waste derived fuel]] from early 2020<ref>[https://www.aggregate.com/news-and-resources/press-releases/cauldon-cement-plant-breaks-ground Aggregate Industries Press Release Accessed 11th June 2021]</ref> | |||

==References== | ==References== | ||

<references /> | <references /> | ||

Latest revision as of 09:50, 10 November 2022

Cauldon Cement Kiln is located in Stoke-on-Trent and is owned by Aggregate Industries.

| Cauldon Cement Kiln | |

See Cement Kilns → page for a larger UK Wide map. | |

| Waste Licence | TP3334AW |

| Operator | Aggregate Industries t/a Lafarge Cement |

| Parent Company | LafargeHolcim |

| Clinker Capacity | 0.9 Mt |

Summary site information collated from a variety of sources.

Overview

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland[1] extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Cauldon started operating in 1957 and up to 2015 had produced 40 million tonnes of clinker through 4 rotary kilns over this period.

Ownership

- 1957 to 2001 BPCM (G&T Earles) (Blue Circle)

- 2001 to 2013 Lafarge

- 2013 to 2015 Lafarge Tarmac

- 2015 to Present LafargeHolcim (Lafarge Cement is part of Aggregate Industries, which itself is owned by LafargeHolcim[2])

The Process at Cauldon

The following summary diagram is from the Aggregate Industries website[3] which is a 'dry process':

Raw Materials

The primary raw materials are Carboniferous Limestone from Cauldon Low Quarry to the south of the site and Carboniferous Shale in a nearby deposit to the north and west of the plant.

Waste Tonnage, EWC List

The table shows a list of the Waste for the Permit TP3334AW, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated in Oct-24. The total reported tonnage arriving at the site was: 120,784.97t.

| EWC Code | Description | Tonnes In |

|---|---|---|

| 10 02 01 | wastes from the processing of slag | 18631.45 |

| 10 12 08 | waste ceramics, bricks, tiles and construction products (after thermal processing) | 8479.68 |

| 16 01 03 | end-of-life tyres | 2657.22 |

| 16 11 01* | carbon-based linings and refractories from metallurgical processes containing dangerous substances | 34.94 |

| 17 01 01 | concrete | 17891.58 |

| 19 02 08* | liquid combustible wastes containing dangerous substances | 14382.65 |

| 19 08 05 | sludges from treatment of urban waste water | 13998.52 |

| 19 12 10 | combustible waste (refuse derived fuel) | 44708.93 |

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit TP3334AW, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated on Oct-24. The total reported tonnage arriving at the site was: 120,784.97t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|---|---|

| 10 02 01 | Lincolnshire | 18272.39 |

| 10 02 01 | Swansea | 359.06 |

| 10 12 08 | Stoke-on-Trent | 8479.68 |

| 16 01 03 | Lancashire | 175 |

| 16 01 03 | Manchester | 587.7 |

| 16 01 03 | West Midlands | 1894.52 |

| 16 11 01* | Cheshire East | 34.94 |

| 17 01 01 | Derbyshire | 7029.1 |

| 17 01 01 | Nottinghamshire | 10862.48 |

| 19 02 08* | Bristol, City of | 2588.36 |

| 19 02 08* | Lancashire | 3798.18 |

| 19 02 08* | Leeds | 22.92 |

| 19 02 08* | Liverpool | 2069.59 |

| 19 02 08* | North West | 4573.14 |

| 19 02 08* | Worcestershire | 1330.46 |

| 19 08 05 | Scotland | 13998.52 |

| 19 12 10 | Bury | 5948.68 |

| 19 12 10 | Stoke-on-Trent | 38760.25 |

In early June 2021 Aggregate Industries confirmed that they had broken ground on a £13m project to increase their ability to handle up to 100,000 tonnes per annum of waste derived fuel from early 2020[4]