Slough Heat & Power: Difference between revisions

No edit summary |

|||

| (9 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category:Biomass EfW Plants]] | A [[Biomass EfW]] facility [[Slough Heat & Power]] is a [[Combined Heat and Power]](CHP) [[EfW ]]facility located in Slough, Berkshire which produces 80MWth and supplies 28 MWe to the National Grid and heat to local sources and has an annual fuel requirement of up to 150,000 tonnes per annum of [[feedstock]]<ref name="LETS">https://www.letsrecycle.com/news/latest-news/wood-sector-faces-slough-switch-to-rdf/ Let's Recycle]</ref>. | ||

{{BiomassPlant|NAME=Slough Heat & Power|id=71}} | [[Category:Biomass EfW Plants]]{{#vardefine: epr|CP3031SX}} | ||

[[File:Slough Heat and Power Plant.jpg|400px|left|Slough Heat and Power Plant]] | {{BiomassPlant|NAME=Slough Heat & Power|id=71|EPR={{#var: epr}}}} | ||

[[File:Slough Heat and Power Plant.jpg|400px|left|Slough Heat and Power Plant]]__TOC__ | |||

<br clear="left"/> | <br clear="left"/> | ||

==Summary== | ==Summary== | ||

A Biomass | A [[Biomass EfW]] facility [[Slough Heat & Power]] is a [[Combined Heat and Power]](CHP) [[EfW ]]facility located in Slough, Berkshire which produces 80MWth and supplies 28 MWe to the National Grid and heat to local sources and has an annual fuel requirement of up to 150,000 tonnes per annum of [[feedstock]]<ref name="LETS" />. A new facility is planned on the site - [[Slough Multifuel EFW]] 'multifuel' site similar to facilities at [[Ferrybridge Multifuel 2 (FM2)|Ferrybridge 1 and 2]] that will use a variety of [[Municipal Solid Waste]] as its fuel sources<ref name="SSE">[https://sse.com/whatwedo/ourprojectsandassets/thermal/SloughMultiFuel/ SSE]</ref>. | ||

In 2008 Scottish and Southern Energy (SSE) acquired Slough Heat and Power (SH&P) from SERGO for £49.25m<ref>https://www.theengineer.co.uk/sse-buys-slough-heat-and-power/</ref>. | In 2008 [[Scottish and Southern Energy]] (SSE) acquired Slough Heat and Power (SH&P) from [[SERGO]] for £49.25m<ref>https://www.theengineer.co.uk/sse-buys-slough-heat-and-power/</ref>. | ||

The plant was converted to renewable fuel in c.2001 at a cost of approximately £30m<ref name="REN">[https://www.renewableenergyworld.com/2008/03/27/biomass-for-business-at-the-uks-largest-biomass-chp-plant-51979/#gref/ Renewable Energy World]</ref> and this led to the development of an innovative, integrated supply chain for secure fuel supply in partnership with local suppliers such as Thames Valley Energy, a not-for-profit renewable energy agency<ref name="REN" />. | The plant was converted to renewable fuel in c.2001 at a cost of approximately £30m<ref name="REN">[https://www.renewableenergyworld.com/2008/03/27/biomass-for-business-at-the-uks-largest-biomass-chp-plant-51979/#gref/ Renewable Energy World]</ref> and this led to the development of an innovative, integrated supply chain for secure fuel supply in partnership with local suppliers such as [[Thames Valley Energy]], a not-for-profit renewable energy agency<ref name="REN" />. | ||

The plant supplies all of the business located on the same trading estate | The plant supplies all of the business located on the same trading estate with heat, electricity and hot water. Over 2000 nearby homes are also supplied with their electricity from the plant via 100 km of underground cable as part of a private electricity network<ref name="REN" />. | ||

==Plant== | ==Plant== | ||

The six boilers and turbines at the SH&P energy center can operate on a wide variety of fuels, ranging from renewable sources such as wood and fibre through to natural gas, coal and distillate. A small amount of natural gas and coal is used to control the boilers. As part of the plant, steam from two wood-fired [[Fluidised Bed]] boilers is directed to a 35 MW pass out steam turbine. A new multi-fuelled vibrating [[grate]] boiler dedicated to burning fibre fuel pellets and wood chip, was commissioned based on a contract under the 4th [[RO|Non-Fossil Fuel Obligation]] scheme<ref name="REN" />. | |||

The total electrical output of the combined system is 50 MWe of which 40 MWe comes from wood chips and 10 MWe from [[Waste Derived Fuel]] (fibre fuel) in addition to 20 MWth<ref name="REN" />. | |||

{{BioSustain|EPR={{#var: epr}}}} | |||

{{EAIn|EPR={{#var: epr}}}} | |||

Whilst all of the tonnage reported was [[Wood Waste]] in the [[Annual Sustainability Report]] and the [[EA]] waste returns, the site notes that it sources pellets from [[Fibre Fuel Limited]], a subsidiary company of SH&P, comprising non-recyclable waxed cardboard, laminates, photographic paper and mixed papers. The pellets also have non-PVC plastics added, up to a volume of 15%, to improve the [[Calorific Value]] of the fuel<ref name="REN" />. | |||

==References== | ==References== | ||

Latest revision as of 08:53, 15 August 2022

A Biomass EfW facility Slough Heat & Power is a Combined Heat and Power(CHP) EfW facility located in Slough, Berkshire which produces 80MWth and supplies 28 MWe to the National Grid and heat to local sources and has an annual fuel requirement of up to 150,000 tonnes per annum of feedstock[1].

| Slough Heat & Power Operational | |

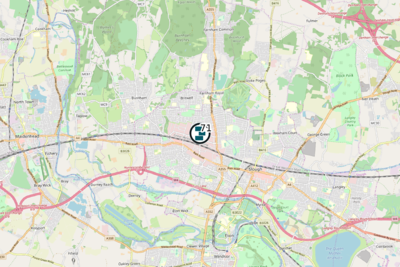

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Slough Heat and Power Ltd (SSE) |

| Capacity | 21 MWe |

| Feedstock | Waste Wood |

| EPR (Waste Licence) | CP3031SX |

| ROC | Yes |

| CfD | |

| CHP | Yes |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|---|---|---|---|---|

| 2017 | 111000 | 0 | 0 | 0 | 111000 |

| 2018 | 111418 | 0 | 0 | 0 | 111418 |

| 2019 | 94531 | 0 | 0 | 0 | 94531 |

| 2020 | 96207 | 0 | 4300 | 0 | 100507 |

| 2021 | 109506 | 0 | 0 | 0 | 109506 |

| 2022 | 102767 | 0 | 0 | 0 | 102767 |

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|---|---|---|---|

| 2017 | 3329 | 3.00% | 2683 | 2.42% |

| 2018 | 3389 | 3.04% | 953 | 0.86% |

| 2019 | 3494 | 3.70% | 6996 | 7.40% |

| 2020 | 4405 | 4.38% | 3127 | 3.11% |

| 2021 | 4302 | 3.93% | 1759 | 1.61% |

| 2022 | 4392 | 4.27% | 2904 | 2.83% |

Summary

A Biomass EfW facility Slough Heat & Power is a Combined Heat and Power(CHP) EfW facility located in Slough, Berkshire which produces 80MWth and supplies 28 MWe to the National Grid and heat to local sources and has an annual fuel requirement of up to 150,000 tonnes per annum of feedstock[1]. A new facility is planned on the site - Slough Multifuel EFW 'multifuel' site similar to facilities at Ferrybridge 1 and 2 that will use a variety of Municipal Solid Waste as its fuel sources[2].

In 2008 Scottish and Southern Energy (SSE) acquired Slough Heat and Power (SH&P) from SERGO for £49.25m[3].

The plant was converted to renewable fuel in c.2001 at a cost of approximately £30m[4] and this led to the development of an innovative, integrated supply chain for secure fuel supply in partnership with local suppliers such as Thames Valley Energy, a not-for-profit renewable energy agency[4].

The plant supplies all of the business located on the same trading estate with heat, electricity and hot water. Over 2000 nearby homes are also supplied with their electricity from the plant via 100 km of underground cable as part of a private electricity network[4].

Plant

The six boilers and turbines at the SH&P energy center can operate on a wide variety of fuels, ranging from renewable sources such as wood and fibre through to natural gas, coal and distillate. A small amount of natural gas and coal is used to control the boilers. As part of the plant, steam from two wood-fired Fluidised Bed boilers is directed to a 35 MW pass out steam turbine. A new multi-fuelled vibrating grate boiler dedicated to burning fibre fuel pellets and wood chip, was commissioned based on a contract under the 4th Non-Fossil Fuel Obligation scheme[4].

The total electrical output of the combined system is 50 MWe of which 40 MWe comes from wood chips and 10 MWe from Waste Derived Fuel (fibre fuel) in addition to 20 MWth[4].

Annual Sustainability Tonnage Input/Fuel

The tonnage[5] received by the plant in the most recent Annual Sustainability Report and for the previous 3 years for 2020/21 was reported by Ofgem as below[6]:

| Year | Waste Wood (m3) | Waste Wood (t) | Straw | Miscanthus | Arboricultrual Waste | Sawmill Residue | Foresrty Residue | Round Wood | Short Rotation Coppice | MBM | Other Material |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 2020/21 | 0 | 92117 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2019/20 | 0 | 95287 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2018/19 | 0 | 98812 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 2017/18 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit CP3031SX, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data was last updated on Oct-24. The total reported tonnage arriving at the site was: 124,911.41t.

Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|---|---|

| 15 01 03 | Hounslow | 11166.84 |

| 15 01 03 | Lewisham | 1155.82 |

| 15 01 03 | London | 7428.07 |

| 17 02 01 | Slough | 9180.58 |

| 19 12 07 | Bracknell Forest | 10025.5 |

| 19 12 07 | Fareham | 266.44 |

| 19 12 07 | Hampshire | 20765.84 |

| 19 12 07 | Hounslow | 3017.73 |

| 19 12 07 | Lewisham | 2608.23 |

| 19 12 07 | London | 40592.04 |

| 19 12 07 | Suffolk | 2807.08 |

| 19 12 07 | Wiltshire | 15897.24 |

Whilst all of the tonnage reported was Wood Waste in the Annual Sustainability Report and the EA waste returns, the site notes that it sources pellets from Fibre Fuel Limited, a subsidiary company of SH&P, comprising non-recyclable waxed cardboard, laminates, photographic paper and mixed papers. The pellets also have non-PVC plastics added, up to a volume of 15%, to improve the Calorific Value of the fuel[4].

References

- ↑ 1.0 1.1 https://www.letsrecycle.com/news/latest-news/wood-sector-faces-slough-switch-to-rdf/ Let's Recycle]

- ↑ SSE

- ↑ https://www.theengineer.co.uk/sse-buys-slough-heat-and-power/

- ↑ 4.0 4.1 4.2 4.3 4.4 4.5 Renewable Energy World

- ↑ In the case of EfW plants with gasification technology the figures are reported in terms of cubic metres of syngas produced rather than tonnes used

- ↑ Biomass Sustainability Dataset 2020-21