Solid Recovered Fuel: Difference between revisions

m add page specific text |

Additon of text |

||

| Line 1: | Line 1: | ||

[[Category:Tonnage & Waste Types]] | [[Category:Tonnage & Waste Types]] | ||

Solid Recovered Fuel (SRF) is distinct from [[RDF]] in that its quality as a fuel is far | Solid Recovered Fuel (SRF) is distinct from [[RDF]] in that its quality as a fuel is far superior. It is typically used in processes that require a high quality, small particle size, high [[Calorific Value]], low [[Moisture Content]] material – such as cement kilns and new-generation [[ATT]] plants. | ||

Solid Recovered Fuels are covered by international technical specifications which set, amongst other parameters, the chemical and physical parameters of an SRF <ref>[https://www.iso.org/committee/5960430.html] ISO/TC 300 Solid Recoverd Fuels </ref> | |||

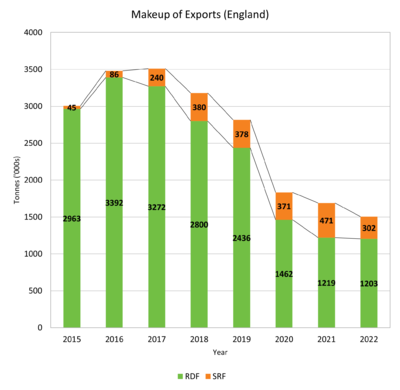

Whilst the data for SRF is often reported within the overall [[Waste Derived Fuel]]/[[RDF]] statistics, there is increasing evidence of a proportional growth in SRF production in the context of a reduction in [[RDF]] export<ref>CIWM Presidential Report 2018 – RDF Trading in a Modern World</ref>. | Whilst the data for SRF is often reported within the overall [[Waste Derived Fuel]]/[[RDF]] statistics, there is increasing evidence of a proportional growth in SRF production in the context of a reduction in [[RDF]] export<ref>CIWM Presidential Report 2018 – RDF Trading in a Modern World</ref>. | ||

Revision as of 12:23, 4 March 2020

Solid Recovered Fuel (SRF) is distinct from RDF in that its quality as a fuel is far superior. It is typically used in processes that require a high quality, small particle size, high Calorific Value, low Moisture Content material – such as cement kilns and new-generation ATT plants.

Solid Recovered Fuels are covered by international technical specifications which set, amongst other parameters, the chemical and physical parameters of an SRF [1]

Whilst the data for SRF is often reported within the overall Waste Derived Fuel/RDF statistics, there is increasing evidence of a proportional growth in SRF production in the context of a reduction in RDF export[2].

Typical differences in the key parameters of RDF and SRF mentioned above are broadly as follows:

| Parameter | RDF Example | SRF Example |

|---|---|---|

| CV | 11 MJ/kg | 18 MJ/kg |

| Moisture Content | 25% | 15% |

| Particle Size | 300mm | 40mm |

Increasingly the market is considering further refinement of SRF which has been made into a pellet for ease of storage, haulage, and introduction into a Cement Kiln, with some companies seeking to achieve End of Waste classification that would then enable the material to be used in other applications as a blended substitute for coal - an example of this is Subcoal [3].

References

- ↑ [1] ISO/TC 300 Solid Recoverd Fuels

- ↑ CIWM Presidential Report 2018 – RDF Trading in a Modern World

- ↑ N+P website