Cement Kilns: Difference between revisions

Arctellion (talk | contribs) No edit summary |

m add page specific text |

||

| Line 1: | Line 1: | ||

The production of cement utilizes waste materials in two primary ways, firstly using specific [[Industrial Waste]] and [[Mineral Waste]] as additives and replacement for traditional raw materials, and secondly as a fuel to substitute for the use of traditional fossil fuels in a cement kiln. In 2018 1,414,195 tonnes of waste was used as raw materials and fuel in the production of cement, with just over 43% of kiln thermal input replaced by [[Waste Derived Fuel]] <ref>[https://cement.mineralproducts.org/documents/MPA_Cement_SD_Report_2019.pdf MPA Cement Sustainability report 2019]</ref>. | |||

[[Category:Technologies & Solutions]] | [[Category:Technologies & Solutions]] | ||

==The Process== | |||

==List of Cement Kilns== | ==List of Cement Kilns== | ||

{{#clear_external_data:}} | {{#clear_external_data:}} | ||

Revision as of 16:06, 7 April 2020

The production of cement utilizes waste materials in two primary ways, firstly using specific Industrial Waste and Mineral Waste as additives and replacement for traditional raw materials, and secondly as a fuel to substitute for the use of traditional fossil fuels in a cement kiln. In 2018 1,414,195 tonnes of waste was used as raw materials and fuel in the production of cement, with just over 43% of kiln thermal input replaced by Waste Derived Fuel [1].

The Process

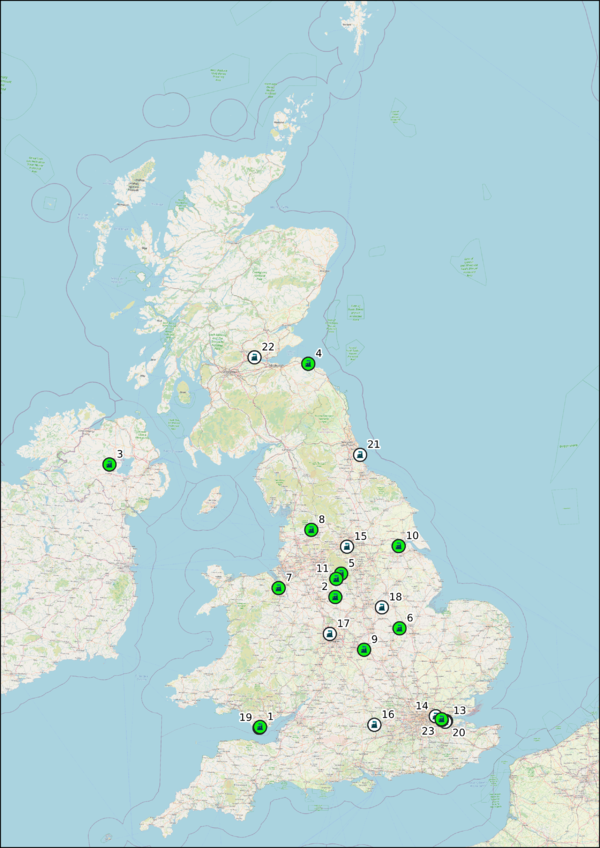

List of Cement Kilns

More detailed information can be found by clicking through to the site-specific page: