Western Wood Energy Plant: Difference between revisions

draft text added to page as template |

m add page specific text |

||

| Line 5: | Line 5: | ||

==Summary== | ==Summary== | ||

A [[Biomass Waste EFW]] facility based upon the co-firing of | A [[Biomass Waste EFW]] facility based upon the co-firing of virgin wood and forestry processing rejects, with only small amounts of clean [[Wood Waste]] to generate 14MWe<ref>[https://www.eco2uk.com/projects/biomass/western-wood-energy-plant/ ECO2 Website: Western wood Plant]</ref>. The [[Forestry Commission]] is the largest fuel supplier to the plant. | ||

The | The Western Wood facility is owned by [[Western Bioenergy Ltd]] and [[Good Energies(UK) LLP]] is the principle shareholder (with a minority interest by [[Western Log Group]] who originally developed the project). [[ECO2]] joined the project between 2004 and 2014 for fuel logistics and administration - the plant is now owned and operated by [[Greensphere Capital LLP]]. | ||

==Plant== | ==Plant== | ||

The plant commenced construction in October 2006 and as fully operational in November 2008. The plant cost £33m to construct via an [[EPC]] consortium contract between [[Aalborg Energie Technik]] (AET) and [[Burmeister & Wain Scandinavian Contractor]] (BWSC). It is based on coventional combustion via an advanced grate that processes 20 tonnes per hour of wood chips, with a steam turbine from [[Mitsui Engineering & Shipbuilding]]<ref>[https://www.renewable-technology.com/projects/western-wood-energy-biomass-wales/ Renewable Technology Website]</ref>. | |||

==Tonnage Input/Fuel== | ==Tonnage Input/Fuel== | ||

The tonnage received by the plant is a mixture of [[Biomass]] and in the most recent [[Annual Sustainability Report]] for 2018-19<ref>[https://www.ofgem.gov.uk/publications-and-updates/biomass-sustainability-dataset-2018-19 Biomass Sustainability Dataset 2018-19]</ref> [[Ofgem]] reported the following fuel received ([[Wood Waste]] representing | The tonnage received by the plant is a mixture of [[Biomass]] and in the most recent [[Annual Sustainability Report]] for 2018-19<ref>[https://www.ofgem.gov.uk/publications-and-updates/biomass-sustainability-dataset-2018-19 Biomass Sustainability Dataset 2018-19]</ref> [[Ofgem]] reported the following fuel received ([[Wood Waste]] representing 7% of input): | ||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

! Biomass !! Tonnage (2018-19) | ! Biomass !! Tonnage (2018-19) | ||

|- | |- | ||

| [[Wood Waste]] || ''' | | [[Wood Waste]] || '''9,744''' | ||

|- | |- | ||

| | | Virgin Wood || 104,038 | ||

|- | |- | ||

| | | Virgin Wood Chips|| 17,971 | ||

|- | |- | ||

| | | Brash|| 4,216 | ||

|- | |- | ||

| Total|| | | Total||135,969 | ||

|} | |} | ||

The [[Wood Waste | The [[Wood Waste]] tonnage received cannot be directly compared with the stated historical tonnage received and recorded in the [[NRW]] statistics as these are recorded on a calendar year basis (i.e. January 2018 to December 2018) and were not available for the period. | ||

==References== | ==References== | ||

<references /> | <references /> | ||

Revision as of 12:21, 26 April 2020

| Error: no local variable "site" has been set. Error: no local variable "status" has been set. | |

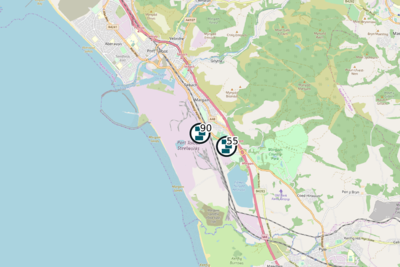

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Error: no local variable "operator" has been set. |

| Capacity | Error: no local variable "capacity" has been set. MWe |

| Feedstock | Error: no local variable "mainfeed" has been set. |

| EPR (Waste Licence) | Error: no local variable "epr" has been set. |

| ROC | Error: no local variable "roc" has been set. |

| CfD | Error: no local variable "cfdcap" has been set. |

| CHP | Error: no local variable "chp" has been set. |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

A Biomass Waste EFW facility based upon the co-firing of virgin wood and forestry processing rejects, with only small amounts of clean Wood Waste to generate 14MWe[1]. The Forestry Commission is the largest fuel supplier to the plant.

The Western Wood facility is owned by Western Bioenergy Ltd and Good Energies(UK) LLP is the principle shareholder (with a minority interest by Western Log Group who originally developed the project). ECO2 joined the project between 2004 and 2014 for fuel logistics and administration - the plant is now owned and operated by Greensphere Capital LLP.

Plant

The plant commenced construction in October 2006 and as fully operational in November 2008. The plant cost £33m to construct via an EPC consortium contract between Aalborg Energie Technik (AET) and Burmeister & Wain Scandinavian Contractor (BWSC). It is based on coventional combustion via an advanced grate that processes 20 tonnes per hour of wood chips, with a steam turbine from Mitsui Engineering & Shipbuilding[2].

Tonnage Input/Fuel

The tonnage received by the plant is a mixture of Biomass and in the most recent Annual Sustainability Report for 2018-19[3] Ofgem reported the following fuel received (Wood Waste representing 7% of input):

| Biomass | Tonnage (2018-19) |

|---|---|

| Wood Waste | 9,744 |

| Virgin Wood | 104,038 |

| Virgin Wood Chips | 17,971 |

| Brash | 4,216 |

| Total | 135,969 |

The Wood Waste tonnage received cannot be directly compared with the stated historical tonnage received and recorded in the NRW statistics as these are recorded on a calendar year basis (i.e. January 2018 to December 2018) and were not available for the period.