Markley Group Biomass: Difference between revisions

m minor text changes |

m Update links |

||

| Line 12: | Line 12: | ||

==Plant== | ==Plant== | ||

The plant was commissioned by UK-based Indusvent Limited who were instructed to design, supply and install a complete turnkey project whcih included a dust extraction and filtration system for production machinery, a sealed chipboard dust and chips transportation system, a 300m<sup>3</sup> storage silo with hydraulic moving floor discharge, shredding of off-cuts and burning of the collected material to provide hot water and heating for both the office and factory heating<ref>[http://www.indusvent.com/project-installations/biomass/energy-efficient-2-1-mw-biomass-plant-for-premiere-kitchens.aspx | The plant was commissioned by UK-based Indusvent Limited who were instructed to design, supply and install a complete turnkey project whcih included a dust extraction and filtration system for production machinery, a sealed chipboard dust and chips transportation system, a 300m<sup>3</sup> storage silo with hydraulic moving floor discharge, shredding of off-cuts and burning of the collected material to provide hot water and heating for both the office and factory heating<ref>[http://www.indusvent.com/project-installations/biomass/energy-efficient-2-1-mw-biomass-plant-for-premiere-kitchens.aspx]</ref>. The system features a 2.1 MW hot water boiler manufactured by Danish based Justsen Energiteknik A/S<ref name="BIO" />. The burning of the waste wood in the boiler is controlled automatically to maximise efficiency with results monitored both on site and at the manufacturers premises in Denmark<ref name="BIO" />. | ||

==Local Authority Users== | ==Local Authority Users== | ||

Revision as of 10:28, 27 April 2020

| Error: no local variable "site" has been set. Error: no local variable "status" has been set. | |

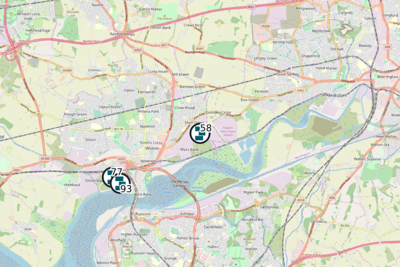

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Error: no local variable "operator" has been set. |

| Capacity | Error: no local variable "capacity" has been set. MWe |

| Feedstock | Error: no local variable "mainfeed" has been set. |

| EPR (Waste Licence) | Error: no local variable "epr" has been set. |

| ROC | Error: no local variable "roc" has been set. |

| CfD | Error: no local variable "cfdcap" has been set. |

| CHP | Error: no local variable "chp" has been set. |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

A biomass EFW located at Markey Group premises in Hardwicke, Gloucestershire which generates 2.1MW from c. 2,300 tonnes of waste wood from its commercial business[1].

In 2012, Gloucester based Markey Group opened a £1.1m biomass facility which runs on waste wood generated by the subsidiary of Markey Group, Premiere Kitchens[1]. Each year Premiere Kitchens creates approximately 2,350 tonnes of waste wood in the form of extracted chipboard dust and residual off-cuts, which is used in the plant to generate all of the heating and hot water required for the company's site at Hardwicke[1].

Following the installation of the biomass facility, Markey Group were able to remove its mains gas supply and as a result the company reduces its carbon emissions by more than c.1,200 tonnes per year[1].

Plant

The plant was commissioned by UK-based Indusvent Limited who were instructed to design, supply and install a complete turnkey project whcih included a dust extraction and filtration system for production machinery, a sealed chipboard dust and chips transportation system, a 300m3 storage silo with hydraulic moving floor discharge, shredding of off-cuts and burning of the collected material to provide hot water and heating for both the office and factory heating[2]. The system features a 2.1 MW hot water boiler manufactured by Danish based Justsen Energiteknik A/S[1]. The burning of the waste wood in the boiler is controlled automatically to maximise efficiency with results monitored both on site and at the manufacturers premises in Denmark[1].

Local Authority Users

As this is a private biomass boiler served only by offcuts from the commercial organisation it serves, there are no local authority users.