Catalytic depolymerization: Difference between revisions

No edit summary |

m minor text change |

||

| Line 1: | Line 1: | ||

[[Category:Technologies & Solutions]] | [[Category:Technologies & Solutions]] | ||

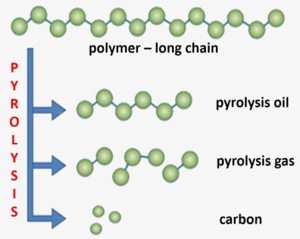

Catalytic | [[Catalytic depolymerization]] is a low temperature processing line used to break down waste plastics from the polymer chains to the hydrocarbon products ([[pyrolysis]]), which are pyrolysis oil, pyrolysis gas and a solid residue-carbon. This process is carried out at lower temperatures of 400-500°C so heating rather than burning occurs which means this technology does not produce harmful emissions or negatively impact the environment.<ref name="ref1">[https://www.lbgmoravia.cz/en/technology/waste-processing/depolymerization-of-plastics-p53/ Plastic depolymerization]</ref> | ||

[[File:Catalytic Depolymerization.png|300px|left|Plastic depolymerization process. All rights reserved.]] | [[File:Catalytic Depolymerization.png|300px|left|Plastic depolymerization process. All rights reserved.]] | ||

Revision as of 14:07, 9 December 2020

Catalytic depolymerization is a low temperature processing line used to break down waste plastics from the polymer chains to the hydrocarbon products (pyrolysis), which are pyrolysis oil, pyrolysis gas and a solid residue-carbon. This process is carried out at lower temperatures of 400-500°C so heating rather than burning occurs which means this technology does not produce harmful emissions or negatively impact the environment.[1]

The Catalyst

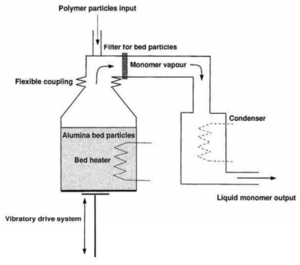

A catalyst is used to support the endothermic cracking (breakdown of hydrocarbon molecules) because it results in the reaction products achieving greater uniformity. The catalyst is continuously added to the process, which ensures continuous and stable activity, and so balanced thermal conditions with a favourable effect on uniform product quality. Also, the catalyst lowers the transformation reaction temperature from around 800°C to temperatures in the range of 400-500°C. The lower temperature then results in reduced fuel consumption for heating.[1][2]

Products

After initial melting the plastics form very viscous liquids, including gasoline and oil fraction which are valuable raw materials for further use in the petrochemical and energy industries, as a component in the production of fuels. The vapour-gas phase consists of gaseous hydrocarbons such as methane, ethane, ethylene, propane and isopropylene which can be utilized in the process of heating the raw materials as fuel or it can be used to generate electricity in a cogeneration unit. The remaining plastic slowly crystallizes and precipitates as a sediment containing solid residue-carbon. The yield of the liquid product is at least 80 % by weight of the incoming waste plastics (60 % of the heavy fraction and 20 % of the light fraction). Gaseous products represent roughly 10 % of the input raw materials and the remaining 10 % consists of solid carbon products.[1][2]