Cement Kilns: Difference between revisions

Arctellion (talk | contribs) |

m minor text changes |

||

| Line 13: | Line 13: | ||

* Stage 6 - '''Packing and Shipping''': the cement is conveyed from grinding mills to silos where it is then packed in bags. | * Stage 6 - '''Packing and Shipping''': the cement is conveyed from grinding mills to silos where it is then packed in bags. | ||

Some cement kilns send clinker for subsequent grinding, blending and packing at a different site. This might include, for example, the introduction of other materials, such as Blast Furnace Slag to produce a Blast Furnace Cement - a highly sulphate resistant cement that typically has around 65% granulated Blast Furnace Slag mixed with the clinker. Categories of cement materials under BS EN 197-1 <ref>[http://www.bgs.ac.uk/downloads/directDownload.cfm?id=1353&noexcl=true&t=Cement%20raw%20materials%20 Mineral Planning Fact Sheet BGS 2014 Download]</ref> include: | |||

{| class="wikitable" | {| class="wikitable" | ||

| Line 60: | Line 60: | ||

{{#get_db_data: db=engy |from=cementkilns |data=site=site,id=id,company=company,ctype=ctype}} | {{#get_db_data: db=engy |from=cementkilns |data=site=site,id=id,company=company,ctype=ctype}} | ||

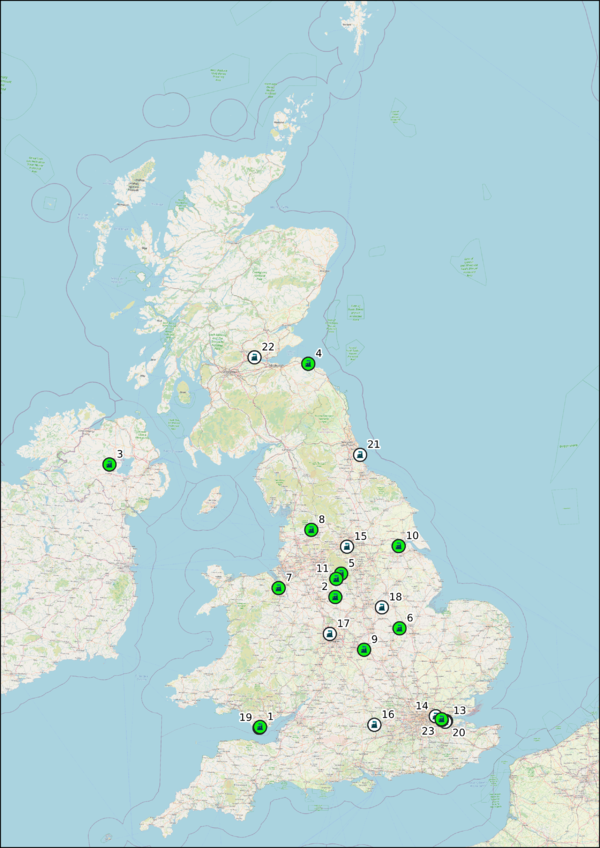

There are 12 operational cement kilns in the UK, listed below and shown on the map, and more detailed information can be found by clicking through to the site-specific page. On the map the grinding & blending sites of the same 5 key operators are also shown coloured green<ref name = ''ref1''/> - these sites do not have a kiln on site and do not have a permit or any record of handling waste: | |||

[[File:Cementkilns.png|600px|right|Cement Kilns in the UK]] | [[File:Cementkilns.png|600px|right|Cement Kilns in the UK]] | ||

{|Class="wikitable" | {|Class="wikitable" | ||

| Line 128: | Line 128: | ||

In the table above the [[EWC]] code for the waste is shown as well as the description - [[Hazardous Waste]] is signified by entries where the six-digit [[EWC]] code is marked by an asterisk (*). Note that the two codes [[EWCChap19|19 12 10]] (generally [[SRF]] and also called [[Climafuel]] by [[Cemex]]) and [[EWCChap19|19 12 12]] (generally [[RDF]], but can be used to describe 'process fines' by some operators) which together account for 318,595 tonnes (or 42% of the tonnage recorded) and comes primarily from the processing of [[Residual Waste]]. The other primary codes used as fuel are [[EWCChap19|19 02 08*]] (the solvent based fuels often known as [[Cemfuel]]) and [[EWCChap16|16 01 03]] (waste tyres) which together account for 153,474 tonnes (or 20% of the tonnage recorded) meaning that of the 753,783 tonnes recorded in 2018, 62% were from 4 waste types that all were used as fuel in the cement process. Tonnage of [[MBM]] and [[Wood Waste]], which may have been higher in previous years are not shown to be so high in 2018, as alternative [[Biomass Waste EFW]] plants have been developed for them that have competed with the cement kilns. | In the table above the [[EWC]] code for the waste is shown as well as the description - [[Hazardous Waste]] is signified by entries where the six-digit [[EWC]] code is marked by an asterisk (*). Note that the two codes [[EWCChap19|19 12 10]] (generally [[SRF]] and also called [[Climafuel]] by [[Cemex]]) and [[EWCChap19|19 12 12]] (generally [[RDF]], but can be used to describe 'process fines' by some operators) which together account for 318,595 tonnes (or 42% of the tonnage recorded) and comes primarily from the processing of [[Residual Waste]]. The other primary codes used as fuel are [[EWCChap19|19 02 08*]] (the solvent based fuels often known as [[Cemfuel]]) and [[EWCChap16|16 01 03]] (waste tyres) which together account for 153,474 tonnes (or 20% of the tonnage recorded) meaning that of the 753,783 tonnes recorded in 2018, 62% were from 4 waste types that all were used as fuel in the cement process. Tonnage of [[MBM]] and [[Wood Waste]], which may have been higher in previous years are not shown to be so high in 2018, as alternative [[Biomass Waste EFW]] plants have been developed for them that have competed with the cement kilns. | ||

==References== | ==References== | ||

<references /> | <references /> | ||

Revision as of 07:51, 21 April 2020

The production of cement utilizes waste materials in two primary ways, firstly using specific Industrial Waste and Mining & Quarrying Waste (and waste from the kiln part of the process itself) as additives and replacement for traditional raw materials, and secondly as a fuel to substitute for the use of traditional fossil fuels in a cement kiln. In 2018 1,414,195 tonnes of waste was used as raw materials and fuel in the production of cement, with just over 43% of kiln thermal input replaced by Waste Derived Fuel. The five companies manufacturing cement together supplied 78% of the cement consumed in the market in 2018. [1]

The Process

There are six main stages of the manufacture of Portland cement[2]:

- Stage 1 - Raw Material Extraction: raw ingredients include limestone, sand and clay, shale, fly ash, mill scale and bauxite. Materials are mined, crushed and reduced in size.

- Stage 2 - Grinding, Proportioning and Blending: the production of a fine homogeneous mix with additives that comprises primarily around 80% limestone and 20% clay.

- Stage 3 - Pre-heating Raw Material: a pre-heating chamber using kiln 'exhaust' gases to reduce energy consumption and pre-condition the raw material into oxides.

- Stage 4 - Kiln Phase: the principle phase which produces a clinker, exiting the kiln in marble-sized nodules - it is the binder that is used in cement products.

- Stage 5 - Cooling and Final Grinding: the clinker is rapidly air-cooled and gypsum (and other active ingredients as required up to around 5%) is added to the clinker and ground to a fine power to produce cement

- Stage 6 - Packing and Shipping: the cement is conveyed from grinding mills to silos where it is then packed in bags.

Some cement kilns send clinker for subsequent grinding, blending and packing at a different site. This might include, for example, the introduction of other materials, such as Blast Furnace Slag to produce a Blast Furnace Cement - a highly sulphate resistant cement that typically has around 65% granulated Blast Furnace Slag mixed with the clinker. Categories of cement materials under BS EN 197-1 [3] include:

| Category | Description of Cement | Proportion of clinker | Proportion of other materials |

|---|---|---|---|

| CEM I | Portland cement | 95 to 100% | 0 to 5% |

| CEM II | Blended cements (sub-divided depending on the material used, e.g. 'Portland fly ash cement', 'Portland slag cement, 'Portland limestone cement' etc) | 65 to 94% | 6 to 35% |

| CEM III | Blastfurnace cement (incorporating ground granulated blastfurnace slags or GGBS) | 5 to 64% | 35 to 95% |

| CEM IV | Pozzolanic cement (incorporating natural or synthetic pozzolanic material e.g. volcanic ash) | 45 to 89% | 11 to 55% |

| CEM V | Composite cement (incorporating both GGBS and pozzolanic material) | 20 to 64% | 18 to 50% GGBS; 18 to 50% Pozzolanic material |

An alternative to Portland cement set out above is the process undertaken at Purfleet cement kiln which is focused on the production of High Alumina Cement (HAC) also known as calcium aluminate cement (CAC). HAC is used for applications that require a resistance to chemical attack[4], and with no evidence of the use of waste in their production, the site at Purfleet is included in WikiWaste for completeness only. Typical uses include[5]:

- a reagent in formulated products

- an hydraulic binder base for refractory and specialty concrete

- an accelerator for Portland cement

In 2018 the UK produced 7,734,000 tonnes of clinker (from a total listed clinker capacity of UK cement kilns of 10,400,000 tonnes or 74% of capacity, excluding Purfleet cement kiln ), leading to to the manufacture and sale of 10,076,000 million tonnes of cement (including 935,000 tonnes of imported cement) by the five main companies in the UK. Imports by others and other cementitious materials (fly ash and GGBS) bought the total UK cementitious materials to 15,188,000 tonnes in 2018[6].

Use of Waste - Historical Context

The introduction of waste materials - or 'Alternative Raw Materials' as coined by the industry - can be as part of the kiln phase or the final grinding stage and it can be used as an additive or as a fuel in the process.

In 1995 there were 20 'cement factories' in the UK producing around 15 million tonnes a year of cement each year, with the cost of energy in the process representing 40 to 50% of running costs. There was a drive to substitute traditional fuels (coal and petroleum coke) with cheaper fuels slightly before this date, and trials were still running at this time with the ramifications of these trials captured in a Parliamentary Briefing Note[7]. Waste Derived Fuel had already started to play a more significant role in UK cement processing, in line with other countries (especially in Europe). It started with the use of solvent based hazardous wastes, often referred to as Cemfuel and by some as a Recycled Liquid Fuel (RLF), which was being trialed at a substitution of 50% of traditional coal fuel (although at the time 100% substitution occurred in Belgium). At around the same time shredded/chipped waste tyres were starting to also be used in some cement kilns as a Waste Derived Fuel as both the solvent based wastes and tyres had a high CV and attracted an income from taking them into a cement kiln. By 1998 the MPA reports that 446,511 tonnes of waste by-products were used as fuel and raw materials, accounting for 4% of cement production and the proportion of fuel comprising waste was 5.7%Cite error: The opening <ref> tag is malformed or has a bad name.

Cement kilns are an option for disposing of hazardous materials because:

- the temperatures in the kiln, which are much higher than in other combustion systems (e.g. incinerators),

- the alkaline conditions in the kiln, afforded by the high-calcium input mix or rawmix, which can absorb acidic combustion products,

- the ability of the clinker to absorb heavy metals into its structure[8]

By 2005 the range of alternative fuels had expanded in Europe to include tyres, plastic, paper, RDF/SRF, dried sewage sludge, meat and bone meal and some other waste streams, with fuel costs typically accounting for 30 to 40% of operating costs[9]. This was driven by the cement industry looking to reduce its costs and carbon emissions to make a more sustainable product, and by changes in the waste sector around the Landfill Directive and the introduction of the Landfill Tax which made cement kilns an alternative outlet for suitably prepared waste materials/Waste Derived Fuel.

By 2010 the MPA reports that 1,528,315 tonnes of waste by-products were used as fuel and raw materials in UK cement manufacture, accounting for 7.2% of cement production and the proportion of fuel comprising waste was 39.7%Cite error: The opening <ref> tag is malformed or has a bad name.

By 2018 the MPA reported there were 12 cement kilns, with 1,414,195 tonnes of recycled content in UK cement manufacture, equivalent to almost 10% of cement production 2018. This same report notes that since 2013 the total waste used has not varied by much more than +/-150,000 tonnes per year, and the proportion fuel comprising waste was 43% in 2018 and has not changed by much more than +/- 1.5% since 2013Cite error: The opening <ref> tag is malformed or has a bad name.

In addition to the use of Waste Derived Fuel in UK cement kilns RDF, and more commonly SRF due to its higher CV and more stringent specification, has been increasingly exported from the UK to Europe since 2009. This has been driven by demand in Europe, combined with a flat demand in the UK cement kilns, and an increasing Landfill Tax that has has made export commercially viable/attractive.

List of UK Cement Kilns

There are 12 operational cement kilns in the UK, listed below and shown on the map, and more detailed information can be found by clicking through to the site-specific page. On the map the grinding & blending sites of the same 5 key operators are also shown coloured greenCite error: The opening <ref> tag is malformed or has a bad name - these sites do not have a kiln on site and do not have a permit or any record of handling waste:

Use of Waste - Current Context

The UK cement kilns, on the whole, have waste permits and complete returns of the waste handled each quarter. The most recent data for each site is listed in the site specific page per cement kiln, although no returns have been made/are available for Cookstown, Purfleet and Dunbar. An analysis of the waste returns for 2018 totals 753,784 tonnes - out of the 1,414,195 tonnes reported by the MPACite error: The opening <ref> tag is malformed or has a bad name. The difference can be accounted for via several factors:

- There are no returns for 3 cement kilns

- The material may not be captured by the waste reports [10]

- The grinding and blending sites are excluded from the analysis

From the information that is available, the following breakdown for cement kilns is as follows:

| EWC Code | Waste Description | Tonnes (2018) |

|---|---|---|

| 01 04 08 | waste gravel and crushed rocks other than those mentioned in 01 04 07 | 796 |

| 02 02 02 | animal-tissue waste - the code typically used for MBM | 1,639 |

| 02 02 03 | materials unsuitable for consumption or processing | 8,360 |

| 06 02 01* | calcium hydroxide | 1,189 |

| 10 01 02 | coal fly ash | 180,493 |

| 10 01 15 | bottom ash, slag and boiler dust from co-incineration other than those mentioned in 10 01 14 | 384 |

| 10 02 13* | sludges and filter cakes from gas treatment containing dangerous substances | 24,172 |

| 16 01 03 | end-of-life tyres | 69,224 |

| 16 08 04 | spent fluid catalytic cracking catalysts (except 16 08 07) | 2,509 |

| 19 01 13* | fly ash containing dangerous substances | 29 |

| 19 02 08* | liquid combustible wastes containing dangerous substances | 84,249 |

| 19 02 10 | combustible wastes other than those mentioned in 19 02 08 and 19 02 09 | 18,643 |

| 19 08 05 | sludges from treatment of urban waste water | 25,522 |

| 19 08 13* | sludges containing dangerous substances from other treatment of industrial waste water | 3,412 |

| 19 09 02 | sludges from water clarification | 3,773 |

| 19 12 01 | paper and cardboard | 5,226 |

| 19 12 04 | plastic and rubber | 5,469 |

| 19 12 10 | combustible waste (refuse derived fuel) - the code typically used for SRF | 251,730 |

| 19 12 11* | other wastes (including mixtures of materials) from mechanical treatment of waste containing dangerous substances | 100 |

| 19 12 12 | other wastes (including mixtures of materials) from mechanical treatment of wastes other than those mentioned in 19 12 11 | 66,865 |

In the table above the EWC code for the waste is shown as well as the description - Hazardous Waste is signified by entries where the six-digit EWC code is marked by an asterisk (*). Note that the two codes 19 12 10 (generally SRF and also called Climafuel by Cemex) and 19 12 12 (generally RDF, but can be used to describe 'process fines' by some operators) which together account for 318,595 tonnes (or 42% of the tonnage recorded) and comes primarily from the processing of Residual Waste. The other primary codes used as fuel are 19 02 08* (the solvent based fuels often known as Cemfuel) and 16 01 03 (waste tyres) which together account for 153,474 tonnes (or 20% of the tonnage recorded) meaning that of the 753,783 tonnes recorded in 2018, 62% were from 4 waste types that all were used as fuel in the cement process. Tonnage of MBM and Wood Waste, which may have been higher in previous years are not shown to be so high in 2018, as alternative Biomass Waste EFW plants have been developed for them that have competed with the cement kilns.

References

- ↑ MPA Cement Sustainability Report 2019

- ↑ https://civiltoday.com/civil-engineering-materials/cement/106-cement-manufacturing-process

- ↑ Mineral Planning Fact Sheet BGS 2014 Download

- ↑ Design Buildings Wiki

- ↑ Imerys Aluminates Website

- ↑ MPA Annual Cementitious 2001-2018

- ↑ Parlimentary Briefing Note 60 April 1995

- ↑ Wikipedia Entry

- ↑ Environment Agency Science report on Solid Waste Derived Fuels in Cement Kilns, an International perspective

- ↑ As an example, Blast Furnace Slag is considered a primary input for this type of cement, it is not defined as waste by the producer and therefore is not normally captured in UK Waste Tonnage figures or waste permit returns