Bag Breaker: Difference between revisions

No edit summary |

m minor text change |

||

| Line 1: | Line 1: | ||

A [[Bag Breaker]] is an automated opening machine that operates at the beginning of [[MRF|MRFs]] and release the contents contained in bagged [[Waste|waste]] into the downstream plant at the required throughput rate. Bagged material is fed into a [[Bag Breaker]] at an evenly metered flow rate and is split open by blades on counter-rotating drums without damaging the [[Waste|waste]]<ref name="ref1">[https://www.okay.co.uk/project/bag-openers/ Bag Openers: [[OKAY Engineering]]]</ref>. | |||

A [[Bag Breaker]] is an automated opening machine that operates at the beginning of [[MRF|MRFs]] and release the contents contained in bagged [[Waste|waste]] into the downstream plant at the required throughput rate. Bagged material is fed into a [[Bag Breaker]] at an evenly metered flow rate and is split open by blades on counter-rotating drums without damaging the [[Waste|waste]]<ref name="ref1">[https://www.okay.co.uk/project/bag-openers/ Bag Openers: OKAY Engineering]</ref>. Bags of all sizes can be split, and they are left in one or two pieces for easy removal via a series of crowder arms<ref>[https://www.cpmfg.com/recycling-equipment/recycling-sorting-equipment/waste-recycling-equipment/ MSW Bag Opener]</ref>. Conveyors both load the bags and then unload the split material for further processing. The | [[Category:Technologies & Solutions]] | ||

[[File:Bag Opener Blades.png|400px|left|Bag Breaker Blades. Image: OKAY Engineering.]]''Internal View of Machine Showing Bag Breaker Blades''<ref name="ref1" />__TOC__ | |||

<br clear='left'/> | |||

==Overview== | |||

A [[Bag Breaker]] is an automated opening machine that operates at the beginning of [[MRF|MRFs]] and release the contents contained in bagged [[Waste|waste]] into the downstream plant at the required throughput rate. Bagged material is fed into a [[Bag Breaker]] at an evenly metered flow rate and is split open by blades on counter-rotating drums without damaging the [[Waste|waste]]<ref name="ref1"/>. Bags of all sizes can be split, and they are left in one or two pieces for easy removal via a series of crowder arms<ref>[https://www.cpmfg.com/recycling-equipment/recycling-sorting-equipment/waste-recycling-equipment/ MSW Bag Opener - Link to [[CP Group]] Website]</ref>. Conveyors both load the bags and then unload the split material for further processing. The hopper box can be built to match the throughput of the [[MRF]] and so the [[Bag Breaker]] can also perform storage and metering functions to help free up time for the grab/shovel loader downstream<ref name="ref2">[https://www.bulkhandlingsystems.com/wp/wp-content/uploads/2014/07/BHS-Bag-Breaker.pdf Bag Breaker - Link to [[BHS]] Fact Sheet]</ref>. | |||

==Applications== | ==Applications== | ||

| Line 10: | Line 14: | ||

*Feeding<ref name="ref1" /> | *Feeding<ref name="ref1" /> | ||

==Benefits== | ==Stated Benefits== | ||

*Higher processing capacity than manual sorting | *Higher processing capacity than manual sorting | ||

*Low maintenance and operational costs | *Low maintenance and operational costs than a [[shredder]] | ||

*Easy to retrofit into existing facilities | *Easy to retrofit into existing facilities | ||

*Does not damage bagged contents | *Does not damage bagged contents | ||

*Empty bags are torn to large pieces rather than shredded for easy removal | *Empty bags are torn to large pieces rather than shredded for easy removal | ||

*Eliminates the hazard of manual bag opening<ref name="ref2" /> | *Eliminates the hazard of manual bag opening<ref name="ref2" /> | ||

==The Process== | ==The Process== | ||

[[File:Bag Breaker Numbered Diagram.png|400px|right|Bag Breaker Diagram. All Rights Reserved.]] | {| | ||

|- | |||

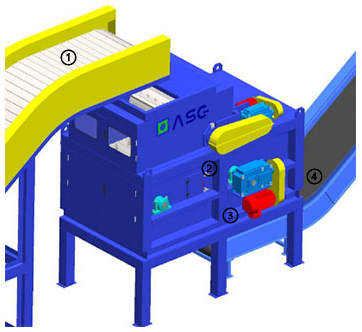

|rowspan=4|[[File:Bag Breaker Numbered Diagram.png|400px|right|Bag Breaker Diagram. All Rights Reserved.]]<br clear=all>''Schematic Diagram of a Bag Breaker''|| 1. Bagged [[Waste|waste]] is fed into the [[Bag Breaker]] via a conveyor at an evenly metered flow rate | |||

|- | |||

| 2. The blades on large counter-rotating drums cut open the bags without damaging the contents | |||

|- | |||

| 3. The [[Waste|waste]] falls from the bottom of the machine | |||

|- | |||

| 4. A belt conveyor transports the [[Recyclables|recyclable]] material away from the machine for further processing downstream<ref name="ref2" /> | |||

|} | |||

==References== | ==References== | ||

<references /> | <references /> | ||

Latest revision as of 07:31, 29 September 2021

A Bag Breaker is an automated opening machine that operates at the beginning of MRFs and release the contents contained in bagged waste into the downstream plant at the required throughput rate. Bagged material is fed into a Bag Breaker at an evenly metered flow rate and is split open by blades on counter-rotating drums without damaging the waste[1].

Internal View of Machine Showing Bag Breaker Blades[1]

Overview

A Bag Breaker is an automated opening machine that operates at the beginning of MRFs and release the contents contained in bagged waste into the downstream plant at the required throughput rate. Bagged material is fed into a Bag Breaker at an evenly metered flow rate and is split open by blades on counter-rotating drums without damaging the waste[1]. Bags of all sizes can be split, and they are left in one or two pieces for easy removal via a series of crowder arms[2]. Conveyors both load the bags and then unload the split material for further processing. The hopper box can be built to match the throughput of the MRF and so the Bag Breaker can also perform storage and metering functions to help free up time for the grab/shovel loader downstream[3].

Applications

Stated Benefits

- Higher processing capacity than manual sorting

- Low maintenance and operational costs than a shredder

- Easy to retrofit into existing facilities

- Does not damage bagged contents

- Empty bags are torn to large pieces rather than shredded for easy removal

- Eliminates the hazard of manual bag opening[3]

The Process

Schematic Diagram of a Bag Breaker |

1. Bagged waste is fed into the Bag Breaker via a conveyor at an evenly metered flow rate |

| 2. The blades on large counter-rotating drums cut open the bags without damaging the contents | |

| 3. The waste falls from the bottom of the machine | |

| 4. A belt conveyor transports the recyclable material away from the machine for further processing downstream[3] |

References

- ↑ 1.0 1.1 1.2 1.3 Bag Openers: OKAY Engineering

- ↑ MSW Bag Opener - Link to CP Group Website

- ↑ 3.0 3.1 3.2 Bag Breaker - Link to BHS Fact Sheet