Magnetic Separator: Difference between revisions

Created page with "A Magnetic Separator is a machine that is used to separate and recover ferrous, magnetic metals such as iron and steel from the Non-Ferrous Metal|non-m..." |

page specific text and links |

||

| Line 1: | Line 1: | ||

A [[Magnetic Separator]] is a machine that is used to separate and recover [[Ferrous Metal|ferrous]], magnetic metals such as iron and steel from the [[Non-Ferrous Metal|non-magnetic]] fraction in the [[Waste|waste]] stream. This is achieved by passing [[Waste|waste]] materials, via a conveyor, over strong magnets. | A [[Magnetic Separator]] is a machine that is used to separate and recover [[Ferrous Metal|ferrous]], magnetic metals such as iron and steel from the [[Non-Ferrous Metal|non-magnetic]] fraction in the [[Waste|waste]] stream. This is achieved by passing [[Waste|waste]] materials, via a conveyor, over or under strong magnets. | ||

[[Category:Technologies & Solutions]] | [[Category:Technologies & Solutions]] | ||

[[File:Crossbelt-overband-in-MSW-processing-plant-1087x614.jpg|400px|left|Crossbelt Overband Magnet on MSW - Magnapower Image all rights reserved]]__TOC__ | |||

<br clear='left'/> | |||

==Overview== | ==Overview== | ||

A [[Magnetic Separator]] separates out the [[Ferrous Metal|ferrous]] portion of the [[Waste|waste]] stream from the [[Non-Ferrous Metal|non-ferrous]]. The separation process extracts | A [[Magnetic Separator]] separates out the [[Ferrous Metal|ferrous]] portion of the [[Waste|waste]] stream from the [[Non-Ferrous Metal|non-ferrous]]. The separation process extracts strongly magnetic (ferromagnetic) and even weekly magnetic (paramagnetic) materials by passing the [[Waste|waste]] stream over (or under) powerful magnets<ref name="ref1">[https://onlinelibrary.wiley.com/doi/epdf/10.1002/14356007.b02_19?saml_referrer Magnetic Separation]</ref>. The conventional use of [[Ferrous Metal|magnetic]] separation can be placed into two categories: the purification of feeds with [[Ferrous Metal|magnetic]] components (with the desired product being [[Non-Ferrous Metal|non-magnetic]]) and the concentration of [[Ferrous Metal|magnetic]] materials (with the desired product being [[Ferrous Metal|magnetic]])<ref>[https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=&arnumber=1058315 Magnetic Separation: A Review of Principles, Devices, and Applications]</ref>. Close control of the speed of passage through the magnetic field is essential for efficient sorting/recovery rates<ref>[https://www.sciencedirect.com/science/article/pii/B9780080970530000133 Magnetic and Electrical Separation]</ref>. | ||

==Applications== | ==Applications<ref name="ref2">[https://www.magnapower.com/permanent-overband-magnets/crossbelt-overband-magnet/ Based on Information within Magnapower Website accessed Dec. 2021]</ref>== | ||

* | * Waste management applications - to remove the [[Ferrous Metal|ferrous]] portion from different [[Waste|waste]] materials such as: | ||

*[[Waste]] | ** Dry Recyclables/[[DMR]] (mixed and [[Twin Stream Collection|twin streams]]) | ||

* | ** [[MSW]] | ||

* | ** [[C&I Waste]] | ||

** [[C&D Waste]]/Skip Waste | |||

** [[Waste Derived Fuel]] - to ensure reduction of metal in [[RDF]] and [[SRF]] to meet end specification | |||

* [[Metal|Scrap Metal]] Separation - to remove [[Ferrous Metal|ferrous]] from mixed metal streams | |||

* [[WEEE - Fridges & Freezers|Fridge]] Recycling Plants- to remove [[Ferrous Metal|ferrous]] from mixed metal, plastic and glass stream | |||

* [[Tyres]] Recycling- to remove [[Ferrous Metal|ferrous]] from rubber stream | |||

* [[Incinerator Bottom Ash]] - to remove [[Ferrous Metal|ferrous]] from ash as part of production of [[IBAA]] | |||

* [[Biomass]] - to remove [[Ferrous Metal|ferrous]] from [[Wood Waste]] to ensure purity for onward use | |||

* [[WEEE]] Processing - to remove [[Ferrous Metal|ferrous]] from mixed metal and plastic streams | |||

* Window Frame Recycling - to remove [[Ferrous Metal|ferrous]] from plastic streams | |||

==Benefits== | ==Benefits== | ||

| Line 18: | Line 29: | ||

==The Process== | ==The Process== | ||

There are two primary types of [[Magnetic Separator]]: | |||

* '''Overband Magnets''' (which include electromagnetic overband magnets) - where the waste is passed under a magnet and a rotating conveyor belt pulls the ferrous metal away from the transporting conveyor. There are two types of configuration for overband magnets | |||

** Inline Overband Magnets - where the magnet and extracting conveyor are aligned with the transporting conveyor | |||

** Crossbelt Overband Magnets - where the magnet is at right angles to the transporting conveyor | |||

* '''Drum Magnets''' where the waste is passed over a rotating magnet to pull the ferrous metal away from the transporting conveyor belt | |||

===Overband Magnet=== | |||

{| | |||

|- | |||

|rowspan=4|[[File:Overband-crossbelt-schematic-1024x592.png|400px|left|Overband Cross Belt Schematic - Magnapower Image - all rights reserved]]<br clear=all>''Schematic Diagram of a Crossbelt Magnetic Separator''<ref name="ref2" />|| 1. The feed material is fed onto the conveyor belt and is transported under the magnet.||rowspan=4| | |||

[[File:Overband-with-steel-armoured-belt-2048x1284.jpg|400px|left|Crossbelt Overband Magnet - Magnapower Image - all rights reserved]] | |||

|- | |||

| 2. The [[Ferrous Metal|ferrous]] material is drawn up towards the magnet from the [[Waste|waste]] stream. | |||

|- | |||

| 3. A rotating conveyor with paddles carries the [[Ferrous Metal|ferrous]] material over the side of the transporting conveyor where it drops out of the magnetic field into a separate bin. | |||

|- | |||

| 4. The non-magnetic material continues on the transporting conveyor unaffected by the process. | |||

|} | |||

===Drum Magnet=== | |||

{| | {| | ||

|- | |- | ||

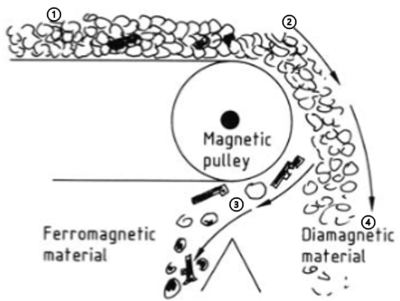

|rowspan=4|[[File:Magnetic Separator Diagram Numbered.png| | |rowspan=4|[[File:Magnetic Separator Diagram Numbered.png|400px|left|Magnetic Separator Diagram. All Rights Reserved.]]<br clear=all>''Schematic Diagram of a Drum Magnetic Separator<ref name="ref1" />''|| 1. The feed material is fed onto the conveyor belt and is transported towards the magnetic pulley end.||rowspan=4| | ||

[[File:Drum-magnet-and-feeder-with-guards-not-fitted-4-1024x681.jpg|350px|left|Drum Magnet - MangnaPower Image, all rights reserved]] | |||

|- | |- | ||

| 2. The [[Waste|waste]] stream falls off the end of the pulley and travels downward by the combined action of gravitational and frictional forces. | | 2. The [[Waste|waste]] stream falls off the end of the pulley and travels downward by the combined action of gravitational and frictional forces. | ||

|- | |- | ||

| 3. Magnetic forces produced by the stationary magnets within the pulley hold the [[Ferrous Metal|ferrous]] material against the rotating drum and deposit them in the [[Ferrous Metal|ferromagnetic]] bin. | | 3. Magnetic forces produced by the stationary magnets within the pulley hold the [[Ferrous Metal|ferrous]] material against the rotating drum and deposit them in the [[Ferrous Metal|ferromagnetic]] bin. | ||

Revision as of 14:42, 30 December 2021

A Magnetic Separator is a machine that is used to separate and recover ferrous, magnetic metals such as iron and steel from the non-magnetic fraction in the waste stream. This is achieved by passing waste materials, via a conveyor, over or under strong magnets.

Overview

A Magnetic Separator separates out the ferrous portion of the waste stream from the non-ferrous. The separation process extracts strongly magnetic (ferromagnetic) and even weekly magnetic (paramagnetic) materials by passing the waste stream over (or under) powerful magnets[1]. The conventional use of magnetic separation can be placed into two categories: the purification of feeds with magnetic components (with the desired product being non-magnetic) and the concentration of magnetic materials (with the desired product being magnetic)[2]. Close control of the speed of passage through the magnetic field is essential for efficient sorting/recovery rates[3].

Applications[4]

- Waste management applications - to remove the ferrous portion from different waste materials such as:

- Dry Recyclables/DMR (mixed and twin streams)

- MSW

- C&I Waste

- C&D Waste/Skip Waste

- Waste Derived Fuel - to ensure reduction of metal in RDF and SRF to meet end specification

- Scrap Metal Separation - to remove ferrous from mixed metal streams

- Fridge Recycling Plants- to remove ferrous from mixed metal, plastic and glass stream

- Tyres Recycling- to remove ferrous from rubber stream

- Incinerator Bottom Ash - to remove ferrous from ash as part of production of IBAA

- Biomass - to remove ferrous from Wood Waste to ensure purity for onward use

- WEEE Processing - to remove ferrous from mixed metal and plastic streams

- Window Frame Recycling - to remove ferrous from plastic streams

Benefits

- Large capacity

- High efficiency

- Continuous process

- Low operating cost[5]

The Process

There are two primary types of Magnetic Separator:

- Overband Magnets (which include electromagnetic overband magnets) - where the waste is passed under a magnet and a rotating conveyor belt pulls the ferrous metal away from the transporting conveyor. There are two types of configuration for overband magnets

- Inline Overband Magnets - where the magnet and extracting conveyor are aligned with the transporting conveyor

- Crossbelt Overband Magnets - where the magnet is at right angles to the transporting conveyor

- Drum Magnets where the waste is passed over a rotating magnet to pull the ferrous metal away from the transporting conveyor belt

Overband Magnet

Schematic Diagram of a Crossbelt Magnetic Separator[4] |

1. The feed material is fed onto the conveyor belt and is transported under the magnet. |

|

| 2. The ferrous material is drawn up towards the magnet from the waste stream. | ||

| 3. A rotating conveyor with paddles carries the ferrous material over the side of the transporting conveyor where it drops out of the magnetic field into a separate bin. | ||

| 4. The non-magnetic material continues on the transporting conveyor unaffected by the process. |

Drum Magnet

Schematic Diagram of a Drum Magnetic Separator[1] |

1. The feed material is fed onto the conveyor belt and is transported towards the magnetic pulley end. |

|

| 2. The waste stream falls off the end of the pulley and travels downward by the combined action of gravitational and frictional forces. | ||

| 3. Magnetic forces produced by the stationary magnets within the pulley hold the ferrous material against the rotating drum and deposit them in the ferromagnetic bin. | ||

| 4. The diamagnetic (non-magnetic) material falls into a separate bin as they are repelled from the magnetic field[1]. |