Magnetic Separator: Difference between revisions

page specific text and links |

→The Process: new links |

||

| Line 30: | Line 30: | ||

==The Process== | ==The Process== | ||

There are two primary types of [[Magnetic Separator]]: | There are two primary types of [[Magnetic Separator]]: | ||

* '''Overband Magnets''' (which include electromagnetic overband magnets) - where the waste is passed under a magnet and a rotating conveyor belt pulls the ferrous metal away from the transporting conveyor. There are two types of configuration for overband magnets | * '''Overband Magnets''' (which include electromagnetic overband magnets) - where the [[waste]] is passed under a magnet and a rotating conveyor belt pulls the [[Ferrous Metal|ferrous metal]] away from the transporting conveyor. There are two types of configuration for overband magnets | ||

** Inline Overband Magnets - where the magnet and extracting conveyor are aligned with the transporting conveyor | ** Inline Overband Magnets - where the magnet and extracting conveyor are aligned with the transporting conveyor | ||

** Crossbelt Overband Magnets - where the magnet is at right angles to the transporting conveyor | ** Crossbelt Overband Magnets - where the magnet is at right angles to the transporting conveyor | ||

Latest revision as of 22:07, 30 December 2021

A Magnetic Separator is a machine that is used to separate and recover ferrous, magnetic metals such as iron and steel from the non-magnetic fraction in the waste stream. This is achieved by passing waste materials, via a conveyor, over or under strong magnets.

Overview

A Magnetic Separator separates out the ferrous portion of the waste stream from the non-ferrous. The separation process extracts strongly magnetic (ferromagnetic) and even weekly magnetic (paramagnetic) materials by passing the waste stream over (or under) powerful magnets[1]. The conventional use of magnetic separation can be placed into two categories: the purification of feeds with magnetic components (with the desired product being non-magnetic) and the concentration of magnetic materials (with the desired product being magnetic)[2]. Close control of the speed of passage through the magnetic field is essential for efficient sorting/recovery rates[3].

Applications[4]

- Waste management applications - to remove the ferrous portion from different waste materials such as:

- Dry Recyclables/DMR (mixed and twin streams)

- MSW

- C&I Waste

- C&D Waste/Skip Waste

- Waste Derived Fuel - to ensure reduction of metal in RDF and SRF to meet end specification

- Scrap Metal Separation - to remove ferrous from mixed metal streams

- Fridge Recycling Plants- to remove ferrous from mixed metal, plastic and glass stream

- Tyres Recycling- to remove ferrous from rubber stream

- Incinerator Bottom Ash - to remove ferrous from ash as part of production of IBAA

- Biomass - to remove ferrous from Wood Waste to ensure purity for onward use

- WEEE Processing - to remove ferrous from mixed metal and plastic streams

- Window Frame Recycling - to remove ferrous from plastic streams

Benefits

- Large capacity

- High efficiency

- Continuous process

- Low operating cost[5]

The Process

There are two primary types of Magnetic Separator:

- Overband Magnets (which include electromagnetic overband magnets) - where the waste is passed under a magnet and a rotating conveyor belt pulls the ferrous metal away from the transporting conveyor. There are two types of configuration for overband magnets

- Inline Overband Magnets - where the magnet and extracting conveyor are aligned with the transporting conveyor

- Crossbelt Overband Magnets - where the magnet is at right angles to the transporting conveyor

- Drum Magnets where the waste is passed over a rotating magnet to pull the ferrous metal away from the transporting conveyor belt

Overband Magnet

Schematic Diagram of a Crossbelt Magnetic Separator[4] |

1. The feed material is fed onto the conveyor belt and is transported under the magnet. |

|

| 2. The ferrous material is drawn up towards the magnet from the waste stream. | ||

| 3. A rotating conveyor with paddles carries the ferrous material over the side of the transporting conveyor where it drops out of the magnetic field into a separate bin. | ||

| 4. The non-magnetic material continues on the transporting conveyor unaffected by the process. |

Drum Magnet

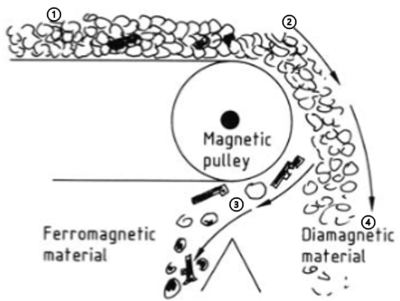

Schematic Diagram of a Drum Magnetic Separator[1] |

1. The feed material is fed onto the conveyor belt and is transported towards the magnetic pulley end. |

|

| 2. The waste stream falls off the end of the pulley and travels downward by the combined action of gravitational and frictional forces. | ||

| 3. Magnetic forces produced by the stationary magnets within the pulley hold the ferrous material against the rotating drum and deposit them in the ferromagnetic bin. | ||

| 4. The diamagnetic (non-magnetic) material falls into a separate bin as they are repelled from the magnetic field[1]. |