Magnetic Separator

A Magnetic Separator is a machine that is used to separate and recover ferrous, magnetic metals such as iron and steel from the non-magnetic fraction in the waste stream. This is achieved by passing waste materials, via a conveyor, over strong magnets.

Overview

A Magnetic Separator separates out the ferrous portion of the waste stream from the non-ferrous. The separation process extracts ferromagnetic (strongly magnetic) and even paramagnetic (weekly attracted by a magnetic field) materials by passing the waste stream over powerful magnets[1]. The conventional use of magnetic separation can be placed into two categories: the purification of feeds with magnetic components (with the desired product being non-magnetic) and the concentration of magnetic materials (with the desired product being magnetic)[2]. Close control of the speed of passage through the magnetic field is essential for efficient sorting/recovery rates[3].

Applications

- Water treatment

- Waste treatment for recovery of ferromagnetic materials

- Removal of paramagnetic impurities

- Chemical processing[1]

Benefits

- Large capacity

- High efficiency

- Continuous process

- Low operating cost[4]

The Process

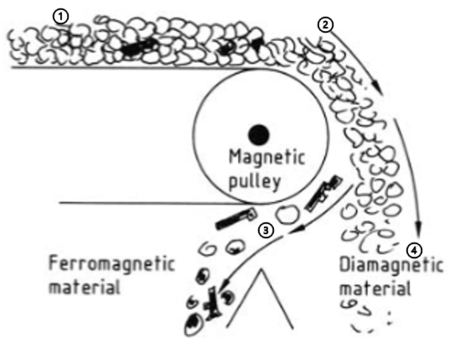

Schematic Diagram of a Magnetic Separator[1] |

1. The feed material is fed onto the conveyor belt and is transported towards the magnetic pulley end. |

| 2. The waste stream falls off the end of the pulley and travels downward by the combined action of gravitational and frictional forces. | |

| 3. Magnetic forces produced by the stationary magnets within the pulley hold the ferrous material against the rotating drum and deposit them in the ferromagnetic bin. | |

| 4. The diamagnetic (non-magnetic) material falls into a separate bin as they are repelled from the magnetic field[1]. |