Cauldon Cement Kiln

| Cauldon Cement Kiln | |

See Cement Kilns → page for a larger UK Wide map. | |

| Waste Licence | TP3334AW |

| Operator | Aggregate Industries t/a Lafarge Cement |

| Parent Company | LafargeHolcim |

| Clinker Capacity | 0.9 Mt |

Summary site information collated from a variety of sources.

Overview

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland[1] extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Cauldon started operating in 1957 and up to 2015 had produced 40 million tonnes of clinker through 4 rotary kilns over this period.

Ownership

- 1957 to 2001 BPCM (G&T Earles) (Blue Circle)

- 2001 to 2013 Lafarge

- 2013 to 2015 Lafarge Tarmac

- 2015 to Present LafargeHolcim (Lafarge Cement is part of Aggregate Industries, which itself is owned by LafargeHolcim[2])

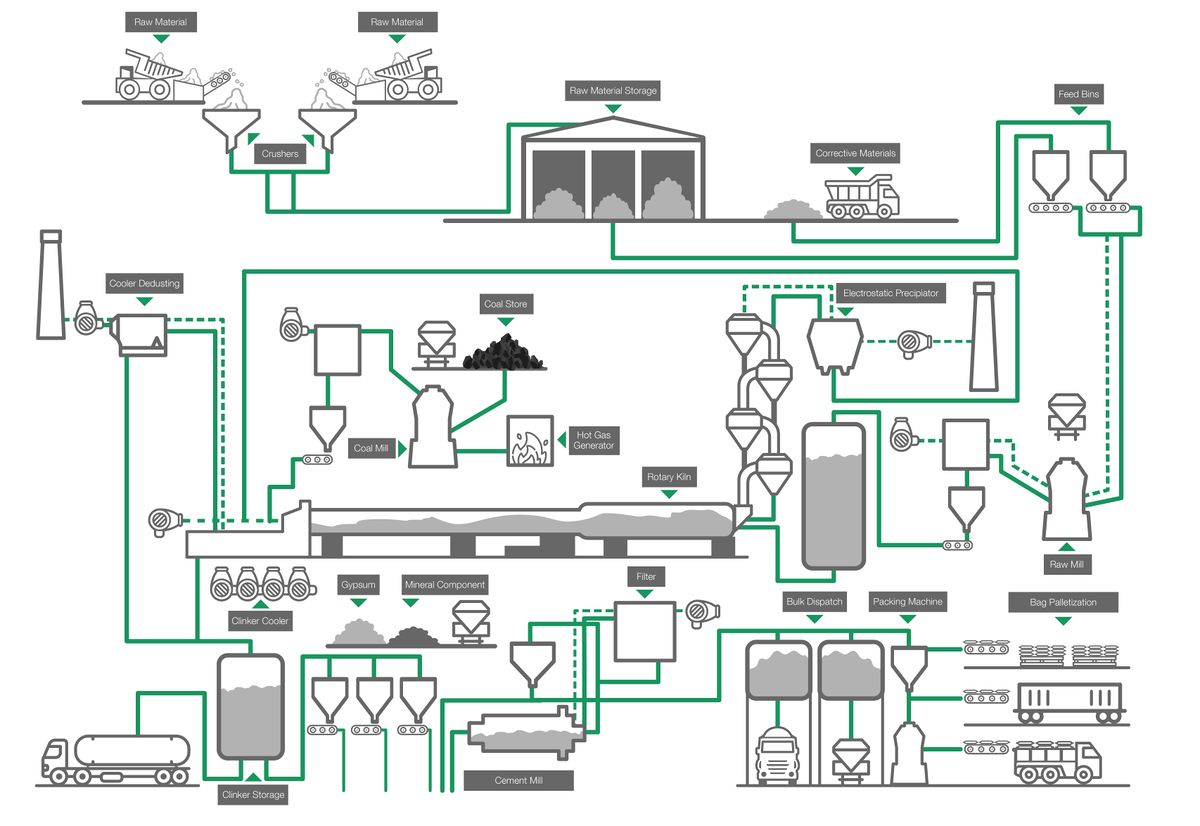

The Process at Cauldon

The following summary diagram is from the Aggregate Industries website[3] which is a 'dry process':

Raw Materials

The primary raw materials are Carboniferous Limestone from Cauldon Low Quarry to the south of the site and Carboniferous Shale in a nearby deposit to the north and west of the plant.

Waste Used on Site

The Cauldon site waste return to the EA for the most recent year showed the following wastes used on site, which were used primary for the purpose of substituting fuel requirements in the plant:

| Waste Class | Description | Tonnage Input |

|---|---|---|

| 16 01 03 | end-of-life tyres | 25,854 |

| 19 02 08* | liquid combustible wastes containing dangerous substances | 12,020 |

| 19 08 05 | sludges from treatment of urban waste water | 23,062 |

| 19 12 10 | combustible waste (refuse derived fuel) | 327 |

In early June 2021 Aggregate Industries confirmed that they had broken ground on a £13m project to increase their ability to handle up to 100,000 tonnes per annum of waste derived fuel from early 2020[4]