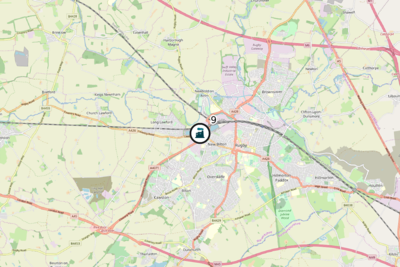

Rugby Cement Kiln

| Rugby Cement Kiln | |

See Cement Kilns → page for a larger UK Wide map. | |

| Waste Licence | BL7248IH |

| Operator | Cemex |

| Parent Company | Cemex SAB de CV |

| Clinker Capacity | 1.5 Mt |

Summary site information collated from a variety of sources.

Overview

WikiWaste has used the website Cement Plants and Kilns in Britain and Ireland[1] extensively for the reference material for each individual cement kiln page. The detail on this reference website is extensive and as WikiWaste is focused upon the UK waste and resource market, only the key highlights are captured from this website (and company websites accordingly) to provide background and context. Rugby started manufacturing clinker in 1870 and up to 2015 had produced 33 million tonnes of clinker through 7 rotary kilns over this period.

Ownership

- 1870 to 1871 Rugby Blue Lias Lime and cement Co. Ltd

- 1871 to 1979 Rugby Portland Cement Co. Ltd

- 1979 to 2000 Rugby Group

- 2000 to 2005 RMC

- 2005 to Present Cemex

The Process at Rugby

The process at the site is an air-separated precalciner kiln, supplied by Polysius which allows for the burning of alternative fuels.

Raw Materials

The primary raw materials were Blue Lias Limestone from a range of quarries over its life near to the site. More recently the raw materials are chalk from Kensworth Quarry (Dunstable) and clay from Southam Quarry[2].

Waste Used on Site

The Rugby site waste return to the EA for the most recent year of 2018 showed 176,851 tonnes of the following wastes used on site, primarily for the primary purpose of substituting fuel requirements in the plant:

| Waste Class | Description | Tonnage Input |

|---|---|---|

| 10 02 13* | sludges and filter cakes from gas treatment containing dangerous substances | 15,209 |

| 16 01 03 | end-of-life tyres | 8,395 |

| 19 12 10 | combustible waste (refuse derived fuel) | 166,098 |

The large proportion of the RDF/SRF used by Cemex (and named by the 'Climafuel') is supplied by Suez from their PPP contracts with Rugby and Birmingham via Malpass Farm site.