Holbrook Community REC

| Error: no local variable "site" has been set. Error: no local variable "status" has been set. | |

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Error: no local variable "operator" has been set. |

| Capacity | Error: no local variable "capacity" has been set. MWe |

| Feedstock | Error: no local variable "mainfeed" has been set. |

| EPR (Waste Licence) | Error: no local variable "epr" has been set. |

| ROC | Error: no local variable "roc" has been set. |

| CfD | Error: no local variable "cfdcap" has been set. |

| CHP | Error: no local variable "chp" has been set. |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

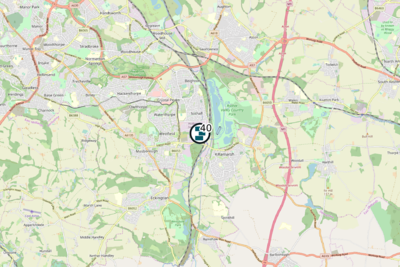

A Biomass EfW facility based on 55,000 tonnes per annum of waste wood producing 6.5 MWe gross power to be exported to the national grid. This facility is a Combined Heat and Power (CHP) plant, enough heat is produced and harnessed to supply approximately 6,700 local homes and commercial properties. Holbrook Community Renewable Energy Centre is located Sheffield[1].

The waste wood feedstock is locally supplied by Mid UK Recycling, a waste management and recycling firm based in the East Midlands. The operator of this facility is Veolia Energy Services Ltd[1].

Plant

The Design and Build EPC contractor for this development was Kandor Energy Ltd[2].

The facility cost £30m to develop and became operational in 2017[3]

The technology utilised in this facility is two water-cooled moving grate furnaces that are supplied by Turboden Srl (part of the Mitsubishi Heavy Industries Group). Turboden Srl also supplied the ‘organic rankine cycle’ (ORC) turbogenerators with air condensers for the facility which uses ‘organic fluid’ vapour as the driving force for the turbine within a closed loop heating circuit[1].

Local Authority Users

References

- ↑ 1.0 1.1 1.2 Date, 2017. Mid UK Supplies Waste Wood For Sheffield Biomass Facility. Online. letsrecycle.com. [Accessed 14 April 2020.]

- ↑ Kandor Energy, 2020. Kantor Energy - Holbrook Community Renewable Energy Centre. Online. Kantorenergy.com. [Accessed 14 April 2020.]

- ↑ Recycling and Waste World, 2017. Sheffield Renewable Energy Centre Opts For Biomass Wood Chip From Mid UK Recycling. Online Recyclingwasteworld.co.uk. [Accessed 14 April 2020.]