Cement Kilns: Difference between revisions

Arctellion (talk | contribs) |

m expanded text |

||

| Line 7: | Line 7: | ||

* Stage 2 - '''Grinding, Proportioning and Blending''': the production of a fine homogeneous mix with additives that comprises primarily around 80% limestone and 20% clay. | * Stage 2 - '''Grinding, Proportioning and Blending''': the production of a fine homogeneous mix with additives that comprises primarily around 80% limestone and 20% clay. | ||

* Stage 3 - '''Pre-heating Raw Material''': a pre-heating chamber using kiln 'exhaust' gases to reduce energy consumption and pre-condition the raw material into oxides. | * Stage 3 - '''Pre-heating Raw Material''': a pre-heating chamber using kiln 'exhaust' gases to reduce energy consumption and pre-condition the raw material into oxides. | ||

* Stage 4 - '''Kiln Phase''': the principle phase which produces a '''clinker''', exiting the kiln in marble-sized nodules - it is the binder that is | * Stage 4 - '''Kiln Phase''': the principle phase which produces a '''clinker''', exiting the kiln in marble-sized nodules - it is the binder that is used in cement products. | ||

* Stage 5 - '''Cooling and Final Grinding''': the clinker is rapidly air-cooled and gypsum (and other active ingredients as required) is added to the clinker and ground to a fine power to produce '''cement''' | * Stage 5 - '''Cooling and Final Grinding''': the clinker is rapidly air-cooled and gypsum (and other active ingredients as required) is added to the clinker and ground to a fine power to produce '''cement''' | ||

* Stage 6 - '''Packing and Shipping''': the cement is conveyed from grinding mills to silos where it is then packed in bags. | * Stage 6 - '''Packing and Shipping''': the cement is conveyed from grinding mills to silos where it is then packed in bags. | ||

Not all cement kilns have the total 'end to end' process on site, with some sites producing the clinker for subsequent grinding, blending and packing at a different site. This might include, for example, the introduction of other materials, such as Blast Furnace Slag to produce a Blast Furnace Cement - a highly sulphate resistant cement that can have up to 65% granulated Blast Furnace Slag mixed with the clinker. | |||

Not all cement kilns | |||

==Use of Waste== | |||

The introduction of waste materials - or 'Alternative Raw Materials' as coined by the industry - can be as part of the kiln phase or the final grinding stage. It can be used as an additive or as a fuel in the process and the percentage of recycled content of cement was reported at 1,414,195 tonnes in UK cement production, equivalent to almost 10% of cement production 2018<ref>[https://cement.mineralproducts.org/documents/MPA_Cement_SD_Report_2019.pdf MPA Cement Sustainability report 2019]</ref>. This same report notes that since 2013 the total waste used has not varied by much more than +/-150,000 tonnes per year, and the proportion fuel comprising waste was 43% in 2018 and has not changed by much more than +/- 1.5% since 2013. | |||

In 1995 there were 20 cement factories producing around 15 million tonnes a year of cement each year and with the cost of energy in the process representing 40 to 50% of running costs there was a drive to substitute traditional fuels (coal and petroleum coke) with cheaper fuels. As a result [[Waste Derived Fuel]] started to play a more significant role in UK cement processing, in line with other countries, especially in Europe<ref>[https://researchbriefings.files.parliament.uk/documents/POST-PN-60/POST-PN-60.pdf Parlimentary Briefing Note 60 April 1995]</ref> which started with the use of solvent based hazardous wastes, named by some operators 'Chemfuel', which were being trialed at a substitution of 50% of traditional coal fuel (although at the time 100% substitution occurred in Belgium). At around the same time shredded/chipped waste [[Tyres|tyres]] were starting to also be used in some cement kilns as a [[Waste Derived Fuel]]. | |||

become a more significant feature in the With fuel costs typically accounting for 30-40% of cement manufacture and with a drive for cement manufacture to become more sustainable and less carbon intensive, so the use of alternative fuels has grown signifciantly since the early 1990's. The use of waste materials in proportionally lower in the UK is lower compared to other European countries. | |||

As Blast Furnace Slag is considered a primary input for this type of cement, it is not defined as waste and therefore is not normally captured in [[UK Waste Tonnage]] figures or waste permit returns. | |||

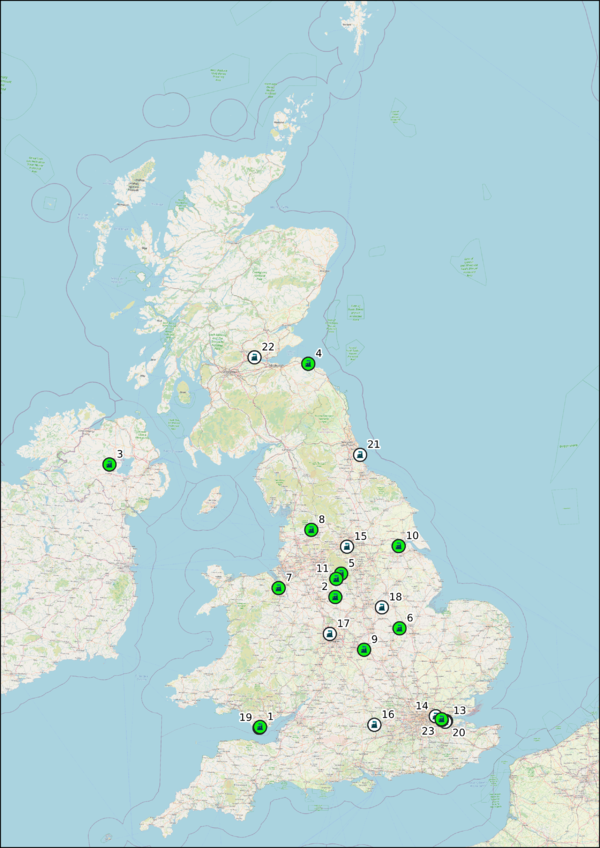

==List of Cement Kilns== | ==List of Cement Kilns== | ||

| Line 61: | Line 67: | ||

|}<ref>[https://cement.mineralproducts.org/documents/MPA_Cement_SD_Report_2019.pdf MPA Cement Sustainability report 2019]</ref>. | |}<ref>[https://cement.mineralproducts.org/documents/MPA_Cement_SD_Report_2019.pdf MPA Cement Sustainability report 2019]</ref>. | ||

==References== | ==References== | ||

<references /> | <references /> | ||

Revision as of 15:03, 8 April 2020

The production of cement utilizes waste materials in two primary ways, firstly using specific Industrial Waste and Mining & Quarrying Waste (and waste from the kiln part of the process itself) as additives and replacement for traditional raw materials, and secondly as a fuel to substitute for the use of traditional fossil fuels in a cement kiln. In 2018 1,414,195 tonnes of waste was used as raw materials and fuel in the production of cement, with just over 43% of kiln thermal input replaced by Waste Derived Fuel. The five companies manufacturing cement together supplied 78% of the cement consumed in the market in 2018. [1].

The Process

There are six main stages of cement manufacture[2]:

- Stage 1 - Raw Material Extraction: raw ingredients include limestone, sand and clay, shale, fly ash, mill scale and bauxite. Materials are mined, crushed and reduced in size.

- Stage 2 - Grinding, Proportioning and Blending: the production of a fine homogeneous mix with additives that comprises primarily around 80% limestone and 20% clay.

- Stage 3 - Pre-heating Raw Material: a pre-heating chamber using kiln 'exhaust' gases to reduce energy consumption and pre-condition the raw material into oxides.

- Stage 4 - Kiln Phase: the principle phase which produces a clinker, exiting the kiln in marble-sized nodules - it is the binder that is used in cement products.

- Stage 5 - Cooling and Final Grinding: the clinker is rapidly air-cooled and gypsum (and other active ingredients as required) is added to the clinker and ground to a fine power to produce cement

- Stage 6 - Packing and Shipping: the cement is conveyed from grinding mills to silos where it is then packed in bags.

Not all cement kilns have the total 'end to end' process on site, with some sites producing the clinker for subsequent grinding, blending and packing at a different site. This might include, for example, the introduction of other materials, such as Blast Furnace Slag to produce a Blast Furnace Cement - a highly sulphate resistant cement that can have up to 65% granulated Blast Furnace Slag mixed with the clinker.

Use of Waste

The introduction of waste materials - or 'Alternative Raw Materials' as coined by the industry - can be as part of the kiln phase or the final grinding stage. It can be used as an additive or as a fuel in the process and the percentage of recycled content of cement was reported at 1,414,195 tonnes in UK cement production, equivalent to almost 10% of cement production 2018[3]. This same report notes that since 2013 the total waste used has not varied by much more than +/-150,000 tonnes per year, and the proportion fuel comprising waste was 43% in 2018 and has not changed by much more than +/- 1.5% since 2013.

In 1995 there were 20 cement factories producing around 15 million tonnes a year of cement each year and with the cost of energy in the process representing 40 to 50% of running costs there was a drive to substitute traditional fuels (coal and petroleum coke) with cheaper fuels. As a result Waste Derived Fuel started to play a more significant role in UK cement processing, in line with other countries, especially in Europe[4] which started with the use of solvent based hazardous wastes, named by some operators 'Chemfuel', which were being trialed at a substitution of 50% of traditional coal fuel (although at the time 100% substitution occurred in Belgium). At around the same time shredded/chipped waste tyres were starting to also be used in some cement kilns as a Waste Derived Fuel.

become a more significant feature in the With fuel costs typically accounting for 30-40% of cement manufacture and with a drive for cement manufacture to become more sustainable and less carbon intensive, so the use of alternative fuels has grown signifciantly since the early 1990's. The use of waste materials in proportionally lower in the UK is lower compared to other European countries.

As Blast Furnace Slag is considered a primary input for this type of cement, it is not defined as waste and therefore is not normally captured in UK Waste Tonnage figures or waste permit returns.

List of Cement Kilns

More detailed information can be found by clicking through to the site-specific page:

List of Grinding and Blending Sites

| Site | Company | Process |

|---|---|---|

| Tilbury | Cemex | Grinding and Blending |

| Dagenham | Breeden | Blending only |

| Dewsbury | Breeden | Blending only |

| Theale | Breeden | Blending only |

| Walsall | Breedon | Blending only |

| Barnstone | Tarmac | Grinding only |

| Celtic Ash | Tarmac | Blending only |

| Northfleet | Tarmac | Blending only |

| Seaham | Tarmac | Blending only |

| Scotash | Tarmac | Blending only |

| West Thorrock | Tarmac | Blending only |

[5].