UPM Shotton Boiler 7: Difference between revisions

→Summary: Additional text. |

|||

| Line 3: | Line 3: | ||

==Summary== | ==Summary== | ||

A Biomass Waste CHP EFW based at the UPM Shotton newsprint mill in Flintshire, north Wales generating 24.8 MWe<ref name="UPM">[https://www.upm.com/news-and-stories/articles/2016/02/increasing-renewable-energy-production-at-shotton/ UPM]</ref> from a feedstock of waste paper, fibre and sludge<ref name="CHP">[https://books.google.co.uk/books?id=CHtwAgAAQBAJ&pg=PA437&lpg=PA437&dq=Power+technology%2BShotton+paper+mill%2BCHP&source=bl&ots=VxBt9DTQPM&sig=ACfU3U35q44SMYAznVy9CIrOu-kPAevvxA&hl=en&sa=X&ved=2ahUKEwj7iNuim-boAhXUSBUIHSAHArMQ6AEwB3oECAsQKQ#v=onepage&q=Power%20technology%2BShotton%20paper%20mill%2BCHP&f=false /Small & Micro CHP Systems]</ref>. The plant provides up to 70% of the paper mill's energy production<ref name="UPM" />. Most of the energy is consumed in the manufacture of mechanical pulp, pumping and paper drying<ref>[https://cld.bz/bookdata/helJYL/basic-html/page-66-67.html#/ UPM Annual Report 2016]</ref>. In 2016 a second steam turbine was brought on line at the facility which utilises excess steam from the biomass CHP plant<ref>[https://www.twosides.info/UK/solar-success-for-upm-shotton/ Two sides]</ref>. | A Biomass Waste CHP EFW based at the UPM Shotton newsprint mill in Flintshire, north Wales generating 24.8 MWe<ref name="UPM">[https://www.upm.com/news-and-stories/articles/2016/02/increasing-renewable-energy-production-at-shotton/ UPM]</ref> from a feedstock of waste paper, fibre and sludge<ref name="CHP">[https://books.google.co.uk/books?id=CHtwAgAAQBAJ&pg=PA437&lpg=PA437&dq=Power+technology%2BShotton+paper+mill%2BCHP&source=bl&ots=VxBt9DTQPM&sig=ACfU3U35q44SMYAznVy9CIrOu-kPAevvxA&hl=en&sa=X&ved=2ahUKEwj7iNuim-boAhXUSBUIHSAHArMQ6AEwB3oECAsQKQ#v=onepage&q=Power%20technology%2BShotton%20paper%20mill%2BCHP&f=false /Small & Micro CHP Systems]</ref>. The plant provides up to 70% of the paper mill's energy production<ref name="UPM" />. Most of the energy is consumed in the manufacture of mechanical pulp, pumping and paper drying<ref>[https://cld.bz/bookdata/helJYL/basic-html/page-66-67.html#/ UPM Annual Report 2016]</ref>. In 2016 a second steam turbine was brought on line at the facility which utilises excess steam from the biomass CHP plant<ref>[https://www.twosides.info/UK/solar-success-for-upm-shotton/ Two sides]</ref>. | ||

The biomass facility cost an estimated £59m<ref>[http://www.downton.co.uk/case-study/upm/ Downtown]</ref>. | |||

==Plant== | ==Plant== | ||

Revision as of 20:40, 13 April 2020

| Error: no local variable "site" has been set. Error: no local variable "status" has been set. | |

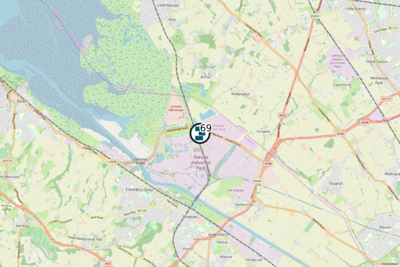

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | Error: no local variable "operator" has been set. |

| Capacity | Error: no local variable "capacity" has been set. MWe |

| Feedstock | Error: no local variable "mainfeed" has been set. |

| EPR (Waste Licence) | Error: no local variable "epr" has been set. |

| ROC | Error: no local variable "roc" has been set. |

| CfD | Error: no local variable "cfdcap" has been set. |

| CHP | Error: no local variable "chp" has been set. |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

A Biomass Waste CHP EFW based at the UPM Shotton newsprint mill in Flintshire, north Wales generating 24.8 MWe[1] from a feedstock of waste paper, fibre and sludge[2]. The plant provides up to 70% of the paper mill's energy production[1]. Most of the energy is consumed in the manufacture of mechanical pulp, pumping and paper drying[3]. In 2016 a second steam turbine was brought on line at the facility which utilises excess steam from the biomass CHP plant[4].

The biomass facility cost an estimated £59m[5].

Plant

The technology in use at the plant is a Bubbling Fluidised bed system[2].

Local Authority Users

The plant manufacturers newsprint solely from recovered paper which is received from a number of local authority contracts throughout the UK.