NIR Optical Sorting: Difference between revisions

m weblink |

|||

| Line 1: | Line 1: | ||

[[Category:Technologies & Solutions]] | [[Category:Technologies & Solutions]] | ||

Near infra-red/[[NIR Optical Sorting]] systems use advanced infra-red sensors to effectively identify materials/[[Feedstock|feedstock]] of different wavelengths. The targeted materials are then ejected through the high-pressure valve to achieve the purpose of sorting<ref>[https://www.hbsorter.com/solution/Nir-Optical-Sorter.html NIR Optical Sorter]</ref>. The first NIR sorting systems were used to process [[Recyclables|recyclable]] materials at the beginning of the 1990s and the technology has developed significantly in the past five years. These systems are frequently used in [[MRF]]s to streamline the sorting process, reduce labour costs, and increase the throughput to make [[Recycling|recycling]] operations more efficient<ref name="ref1">[https://crigler.com/how-optical-sorting-systems-work-for-recycling/ How Optical Sorting Systems Work for Recycling]</ref>. [[NIR Optical Sorting]] systems are capable of processing [[Packaging Waste|packaging]], [[Paper|papers]], [[Waste|waste]] electrical equipment, [[Residual Waste|residual waste]] ([[RDF]]), [[Plastic|plastics]] and vehicle [[Recycling|recycling]]<ref name="ref2">[http://www.wasteminz.org.nz/wp-content/uploads/Ernie-Beker.pdf Automatic Sorting of Recyclable Materials With NIR Technology]</ref>. | Near infra-red/[[NIR Optical Sorting]] systems use advanced infra-red sensors to effectively identify materials/[[Feedstock|feedstock]] of different wavelengths. The targeted materials are then ejected through the high-pressure valve to achieve the purpose of sorting<ref>[https://www.hbsorter.com/solution/Nir-Optical-Sorter.html NIR Optical Sorter]</ref>. The first NIR sorting systems were used to process [[Recyclables|recyclable]] materials at the beginning of the 1990s and the technology has developed significantly in the past five years. These systems are frequently used in [[MRF]]s to streamline the sorting process, reduce labour costs, and increase the throughput to make [[Recycling|recycling]] operations more efficient<ref name="ref1">[https://crigler.com/how-optical-sorting-systems-work-for-recycling/ How Optical Sorting Systems Work for Recycling]</ref>. [[NIR Optical Sorting]] systems are capable of processing [[Packaging Waste|packaging]], [[Paper|papers]], [[Waste|waste]] [[WEEE|electrical equipment]], [[Residual Waste|residual waste]] ([[RDF]]), [[Plastic|plastics]] and vehicle [[Recycling|recycling]]<ref name="ref2">[http://www.wasteminz.org.nz/wp-content/uploads/Ernie-Beker.pdf Automatic Sorting of Recyclable Materials With NIR Technology]</ref>. | ||

==The Principle== | ==The Principle== | ||

Revision as of 16:26, 11 August 2021

Near infra-red/NIR Optical Sorting systems use advanced infra-red sensors to effectively identify materials/feedstock of different wavelengths. The targeted materials are then ejected through the high-pressure valve to achieve the purpose of sorting[1]. The first NIR sorting systems were used to process recyclable materials at the beginning of the 1990s and the technology has developed significantly in the past five years. These systems are frequently used in MRFs to streamline the sorting process, reduce labour costs, and increase the throughput to make recycling operations more efficient[2]. NIR Optical Sorting systems are capable of processing packaging, papers, waste electrical equipment, residual waste (RDF), plastics and vehicle recycling[3].

The Principle

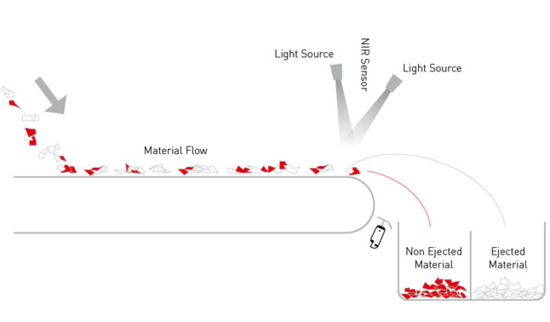

The basic principle behind the NIR technology is measuring the wavelength that bounces off an object. The conveyor moves the material under a bright light which fires near infra-red wavelengths of light at the recyclables. Some of the wavelengths are absorbed while others are reflected by the material. The NIR sensors that are positioned in the last third of the conveyor record the characteristics of the wavelengths bounced back from the material. From there they are able to determine and target the different types of recyclables on the belt[3].

The Process

|

NIR Optical Sorter[4] |

Near Infra-Red/NIR Optical Sorting in the Plastics Recycling Process

NIR sorting is widely used to separate waste plastic streams by using automated equipment that sorts plastic recycling by NIR signature via transmission or reflection. Automatic sorters interface NIR sensing with air nozzles to sort plastic items of various resin compounds. The sensors are positioned above the high-speed conveyor and detect the unique wavelength signature of the desired polymers which subsequently get directed by air jets to their specific waste streams. Contaminants become the waste output or are directed for further processing[5].