Markinch Biomass CHP Plant

A Biomass Cogeneration Combined Heat and Power (CHP) EFW facility Markinch Biomass CHP Plant is based on processing up to 450,000 tonnes per annum of Biomass fuel of which approximately 90% is recovered waste wood and the remainder virgin wood sourced from sustainably manged forests[1].

| Markinch Biomass CHP Plant Operational | |

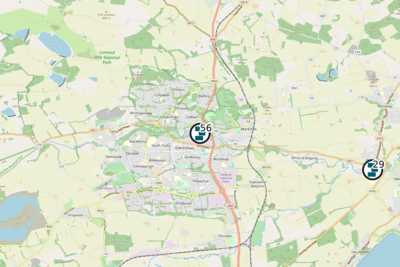

See Biomass EfW → page for a larger UK Wide map. | |

| Operator | RWE |

| Capacity | 61.6 MWe |

| Feedstock | Waste Wood/Virgin |

| EPR (Waste Licence) | PPC/A/1096556 |

| ROC | Yes |

| CfD | |

| CHP | Unkwn |

Operators Annual Report

Input Data

| Year | Wood | Litter | RDF | Other | Total |

|---|

Output Data

| Year | IBA | IBA %ge of Tot IN | APC | APC %ge of Tot IN |

|---|

Summary

A Biomass Cogeneration Combined Heat and Power (CHP) EFW facility Markinch Biomass CHP Plant is based on processing up to 450,000 tonnes per annum of Biomass fuel of which approximately 90% is recovered waste wood and the remainder virgin wood sourced from sustainably manged forests[1].

The facility is located in the small town of Markinch in Fife, Scotland and has an installed capacity of 55 MW. The plant had been generating power to Tullis Russell Papermakers and the local network since February 2014 however, following the paper plants closure the facility has since only been operating in 'power only mode'[1].

The Markinch plant forms part of the Glenrothes Energy Network project and is working in partnership with Fife Council to install heat to a district heating network for Glenrothes through a newly constructed Energy Centre [3] [4].

The owner and operator of the facility is RWE npower renewable, a susbsidiary of RWE Innogy's UK. The plant became operational at the end of 2012[5]. The plant replaces the existing coal-fired plant at the paper mill site and required an investment of approximately £200m[5]. RWE, the owner and operator officially took over the site in November 2010[5].

The project was partially financed by £8.1m of support from the Scottish Government's Regional Selective Assistance (RSA) grant which encourages investment and provides financial support to new and existing businesses that can create or safeguard jobs in designated areas of Scotland[5].

Plant

Markinch Biomass Power Plant uses CHP technology which generates both electricity and heat simultaneously and in doing so generates up to 20% in energy savings[5]. The technology uses a fluidised bed boiler and flue gas systems[5].

Metso power was awarded a contract worth £75m for the delivery of a 155MWth circulating fluidised bed boiler and flue gas treatment plant. Aker Solutions were awarded a £115m contract to provide engineering, procurement and construction (EPC) and project management. It was also responsible for the design, supply, construction, installation and commissioning of the plant[5].

Annual Sustainability Tonnage Input/Fuel

The tonnage[6] received by the plant in the most recent Annual Sustainability Report and for the previous 3 years for Error: no local variable "asyear" has been set. was reported by Ofgem as below[7]:

| Year | Waste Wood (m3) | Waste Wood (t) | Straw | Miscanthus | Arboricultrual Waste | Sawmill Residue | Foresrty Residue | Round Wood | Short Rotation Coppice | MBM | Other Material |

|---|

Waste Tonnage, By Origin

The table shows a list of the Waste for the Permit tbc3, that has arrived into sites as reported to the Regulator and then publicised in their reported statistics. The Data used is from the most recent returns. The total reported tonnage arriving at the site was: Expression error: Unexpected < operator.t. Where this tonnage exceeds that reported in year of the corresponding annual report, this may be due to the following reasons:

- Tonnage may have been received but not incinerated, i.e. the material is held pending incineration (the operator return to the EA reports as received whereas the annual report focuses on when the waste is incinerated.)

- Material may have been received into the site but treated in some other way than incineration.

- Material may have been received on the but transferred out of site for disposal/treatment at another site rather than incineration on the site.

| EWC Code | Origin of Waste | Tonnes In |

|---|

The plant has arranged Wood Waste (including chipboard and MDF) supply agreements with Fife Council, DJ Laing, Stobart Biomass and Suez who are the biggest single supplier, providing 200,000 tonnes of waste wood to the plant every year[8]. Suez has three wood processing facilities for this purpose - Binn Farm in Perthshire, Ellington in Northumberland and Clifton Marshes near Preston[8].

References

- ↑ 1.0 1.1 1.2 RWE

- ↑ Markinch Biomass Plant Site Photo All Rights Reserved

- ↑ https://www.energy-uk.org.uk/publication.html?task=file.download&id=6359

- ↑ https://www.rwe.com/web/cms/mediablob/en/3921924/data/429434/1/rwe-generation-se/fuels/location-overview/uk/markinch-chp-biomass-plant/Energy-Centre-Glenrothes-Energy-Network.pdf

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 5.6 Power Technology

- ↑ In the case of EfW plants with gasification technology the figures are reported in terms of cubic metres of syngas produced rather than tonnes used

- ↑ Biomass Sustainability Dataset 2020-21

- ↑ 8.0 8.1 Bio Fuel Watch